High Voltage Motor: Why is the high voltage motor the core power source of heavy industry?

1.High Voltage Motors: The Backbone of Heavy Industry Power Systems

1.1 Core Power for High-Demand Industrial Applications

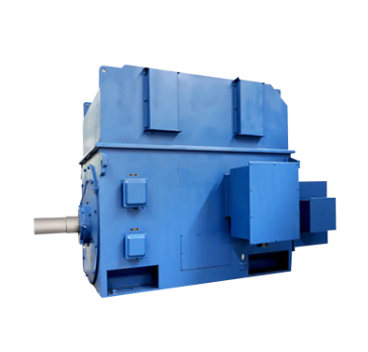

High voltage motors (HVMs) are essential components in industries such as steel manufacturing, mining, chemical processing, and large-scale manufacturing. Unlike low-voltage alternatives, HVMs operate efficiently under higher voltage and power conditions, enabling them to drive heavy-duty machinery and sustain 24/7 operations with minimal fluctuation in performance. Their ability to deliver high torque and constant speed ensures uninterrupted productivity in mission-critical industrial environments.

1.2 Engineering for High Load, High Pressure Environments

Designed to withstand extreme operational pressures, high voltage motors are built with robust mechanical integrity and enhanced load-bearing capabilities. These motors excel in settings where machines must handle intense mechanical stress, including crushers, compressors, and rolling mills. Their advanced insulation systems, rotor balancing, and reinforced stator designs ensure operational integrity under sustained pressure.

1.3 Strategic Design Minimizes Downtime and Operational Risk

The design philosophy behind HVMs emphasizes minimizing downtime caused by mechanical failure or thermal overload. From their bearings to windings, every component is engineered for endurance. Integrated protection systems—such as surge arresters, fault detection modules, and automatic shutdown protocols—provide a layered defense against unexpected events, safeguarding both equipment and operator safety.

2.Reliability and Stability: Sustaining Industrial Momentum Through High Voltage Innovation

2.1 Operational Reliability in Complex Working Conditions

Industrial users rely on high voltage motors for their unparalleled reliability. These motors are often deployed in dusty, humid, or corrosive environments where consistent output is critical. High-grade materials—such as corrosion-resistant alloys and class H insulation—allow HVMs to function continuously without degradation in performance, maintaining uptime for high-output production lines and avoiding costly halts.

2.2 Stable Performance Under Prolonged Stress Loads

The stability of high voltage motors extends to their ability to maintain consistent torque, speed, and thermal equilibrium during extended operations. Even when running at full capacity for weeks, HVMs show minimal thermal distortion or vibration imbalance. This ensures machine precision and reduces secondary damage to connected systems, which is particularly important in synchronized industrial networks.

2.3 Multi-Layered Protection Systems Against Failure Risks

Modern HVMs come equipped with comprehensive protection systems including overload sensors, temperature control units, vibration monitors, and real-time diagnostic feedback. These systems not only prevent major breakdowns but also enable predictive maintenance by alerting operators to early signs of wear or imbalance, reducing long-term repair costs and production delays.

3.Advanced Technology and Durability Define the Future of Industrial Motor Power

3.1 Innovative Designs Optimize Energy Efficiency and Thermal Management

Manufacturers now integrate cutting-edge design techniques to make HVMs more energy-efficient and thermally resilient. Enhanced cooling systems, such as forced air or liquid cooling, and advanced magnetic circuit designs reduce heat generation and energy waste. This results in lower electricity consumption and an extended operational lifespan, key factors in reducing the total cost of ownership.

3.2 Intelligent Control Enhances Operational Flexibility

The integration of smart control systems allows high voltage motors to adapt dynamically to varying load conditions. Through real-time data acquisition and programmable logic controllers (PLCs), motor performance can be adjusted on the fly—optimizing efficiency, reducing stress, and responding to environmental changes. This makes HVMs ideal for modern smart factories and Industry 4.0 frameworks.

3.3 Long-Term Durability Reduces Maintenance and Replacement Costs

Durability is a hallmark of high voltage motor engineering. High-strength alloys, wear-resistant components, and precision machining ensure a prolonged life cycle, even in the harshest conditions. With reduced wear-and-tear, fewer service interventions are needed, translating to lower maintenance costs and higher ROI. Industries that adopt high-voltage motors benefit not only from robust performance but also from long-term capital efficiency.

English

English русский

русский Français

Français عربى

عربى