Why Is the Explosion-Proof Motor Critical for Modern Industry Safety?

Introduction

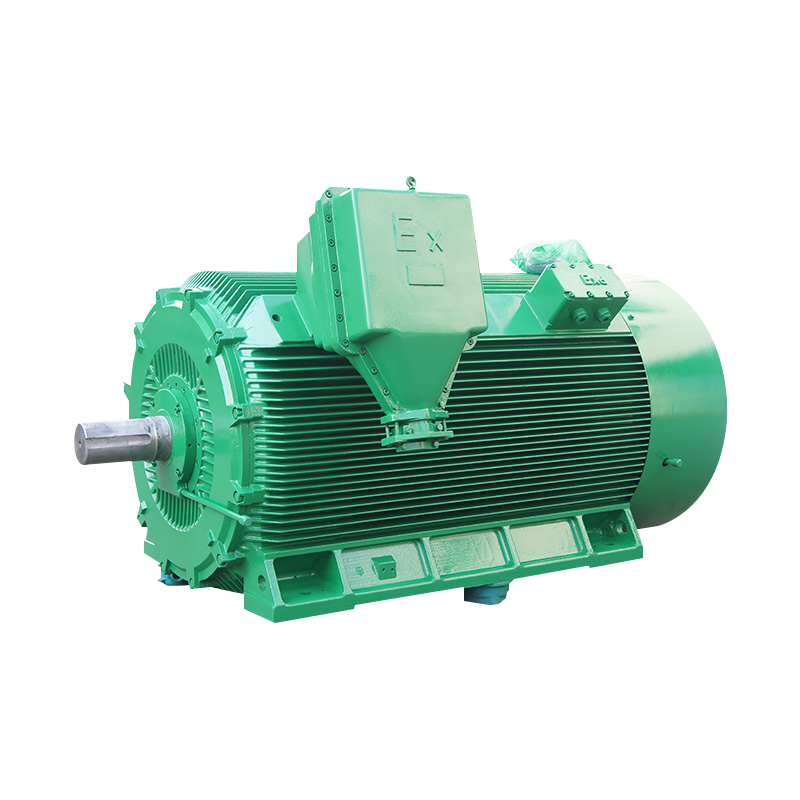

Industrial environments are often filled with potential hazards that can compromise both safety and efficiency. Among the most serious threats are the risks posed by explosive gases, vapors, and dust particles. These elements, when combined with sparks or high surface temperatures, can lead to devastating explosions. To address this, engineers developed a highly specialized technology: the Explosion-proof motor.

An Explosion-proof motor is designed not to prevent an internal ignition from occurring, but rather to contain it within a robust enclosure, preventing it from spreading to the surrounding environment. This engineering solution makes them essential in industries like oil and gas, chemical processing, pharmaceuticals, and mining, where flammable substances are a constant presence.

This comprehensive article explores the science, structure, classifications, certifications, applications, maintenance, and future trends of Explosion-proof motors. It expands on every detail with in-depth knowledge and case-oriented explanations while maintaining an SEO-rich format for maximum online discoverability.

Understanding Hazardous Locations

Hazardous locations (HazLoc) are areas where flammable gases, vapors, or dust particles exist in concentrations that could ignite. For safety, these areas are classified by systems such as the North American Class/Division system and the international Zone system.

Class System

- Class I: Environments with flammable gases or vapors, such as refineries or chemical plants.

- Class II: Areas with combustible dust, such as grain elevators, flour mills, or coal mines.

- Class III: Locations with easily ignitable fibers, such as textile mills or woodworking facilities.

Division System

- Division 1: Hazards are present during normal operations.

- Division 2: Hazards are present only under abnormal conditions, such as equipment malfunctions.

Zone System (IECEx / ATEX)

- Zone 0: Hazard is continuously present.

- Zone 1: Hazard is likely to be present during normal operation.

- Zone 2: Hazard is unlikely to be present under normal conditions.

These classifications guide the proper use of an Explosion-proof motor in environments where ignition risks are elevated.

How Does an Explosion-Proof Motor Work?

The design principle of an Explosion-proof motor is containment, not prevention. Engineers assume that an explosive mixture might enter the motor. If ignition occurs, the casing must withstand the pressure and prevent the flame from escaping.

Key Mechanisms

- Containment: Heavy-duty cast iron or steel enclosures hold the pressure of an internal explosion.

- Flame Path Cooling: Narrow, elongated gaps (flame paths) allow gases to escape while cooling them below ignition temperature.

- Heat Dissipation: The enclosure is designed to prevent its external temperature from exceeding the ignition temperature of the surrounding atmosphere.

By combining these elements, the Explosion-proof motor ensures both reliability and safety in high-risk environments.

Types of Explosion-Proof Motors

Different designs cater to various hazardous conditions, guided by certification standards.

- Totally Enclosed Fan Cooled (TEFC): Uses external fans to dissipate heat without allowing external air to enter the motor.

- XP Motors (Explosion-Proof for Class I, Division 1): Built with rugged housings capable of withstanding high pressures from internal ignition.

- Pressurized or Purged Motors: Maintain a safe internal pressure by filling the enclosure with clean air or inert gas to prevent hazardous gas entry.

- Oil-Immersed Motors: Components are submerged in insulating oil, preventing sparks from igniting external gases.

Comparison Between Explosion-Proof and Standard Motors

Table 1: Functional Comparison

| Feature | Standard Electric Motor | Explosion-Proof Motor |

|---|---|---|

| Safety in Hazardous Areas | Not suitable | Fully safe under hazardous conditions |

| Enclosure Strength | Standard casing | Reinforced, pressure-resistant casing |

| Heat Dissipation | Normal cooling | Specialized cooling to avoid ignition |

| Certification | Not required | UL, CSA, ATEX, IECEx required |

| Cost | Lower | Higher due to safety features |

| Applications | General industry | Oil, gas, chemicals, mining, grain handling |

This comparison highlights why a Explosion-proof motor is indispensable in critical industries.

Applications of Explosion-Proof Motors

Oil and Gas Industry

From drilling rigs to refineries, hydrocarbons create constant explosive risks. Explosion-proof motors power compressors, pumps, and rigs safely.

Chemical Processing

Motors drive agitators and pumps in facilities dealing with volatile chemicals, ensuring safe mixing and transfer.

Mining Operations

Coal mines are notorious for methane gas and dust explosions. These motors keep fans, conveyors, and pumps safe underground.

Grain Handling and Food Processing

Dust particles from flour, grain, and sugar can ignite explosively. Explosion-proof technology prevents industrial accidents in these facilities.

Pharmaceuticals and Aerospace

Used where volatile solvents or propellants must be handled under strict safety standards.

Standards and Certifications

Safety certifications are critical in verifying motor performance under hazardous conditions.

- UL and CSA (North America): Certify motors for hazardous locations.

- ATEX (European Union): Ensures motors meet EU safety directives.

- IECEx (International): Provides global certification aligned with international standards.

Table 2: Certification Overview

| Region | Certification | Key Coverage |

|---|---|---|

| North America | UL, CSA | Class/Division classification |

| Europe | ATEX | Zone system with Groups and Categories |

| Global | IECEx | Internationally harmonized safety |

When selecting an Explosion-proof motor, matching its certification to the hazard classification is essential.

Selecting the Right Explosion-Proof Motor

Several factors guide selection:

- Horsepower and Voltage: Must meet load demands without overloading.

- Enclosure Rating: Should match the hazard classification of the site.

- Cost Balance: While more expensive upfront, long-term safety and compliance outweigh costs.

- Environmental Factors: Humidity, temperature, and dust levels influence choice.

Installation and Maintenance

An Explosion-proof motor only remains safe if installed and maintained properly.

- Installation: Must be grounded, sealed with approved conduits, and installed per safety codes.

- Maintenance: Regular inspection for cracks, corrosion, and flame path cleanliness.

- Troubleshooting: Issues like overheating, vibration, or lubrication failures must be addressed quickly.

Failure to maintain these motors properly can compromise their safety features and create hazards.

Future Trends in Explosion-Proof Motor Technology

The next generation of Explosion-proof motors is being shaped by innovations in materials, design, and digitalization.

- Advanced Materials: Lighter, more heat-resistant alloys are reducing weight without compromising strength.

- Smart Sensors: Integration of IoT-enabled monitoring for predictive maintenance, reducing downtime and costs.

- Energy Efficiency: Development of motors with higher efficiency ratings to meet global sustainability goals.

- Global Standardization: Moves toward unified certification standards to simplify international use.

Conclusion

The Explosion-proof motor is a cornerstone of industrial safety in hazardous environments. By containing potential explosions within their enclosures and preventing external ignition, they protect workers, infrastructure, and the environment. Their use in oil, gas, mining, food processing, and chemical industries highlights their irreplaceable role in modern production.

As industries evolve toward smarter, more sustainable operations, Explosion-proof motors will also evolve—becoming lighter, more efficient, and digitally integrated. For any hazardous environment, they remain not just a choice but a necessity.

English

English русский

русский Français

Français عربى

عربى