What Are the Key Advantages of High‑Voltage Synchronous Motors ?

As global industrial systems demand ever‑higher efficiency, reliability, and performance, High‑Voltage Synchronous Motors have emerged as a cornerstone technology for heavy‑duty applications. These motors are increasingly specified by engineering teams, B2B procurement specialists, and project planners due to their advanced operational advantages and longevity in challenging environments. This article explores not only the core advantages of these machines, but also their applications, selection criteria, maintenance strategies, and common troubleshooting techniques.

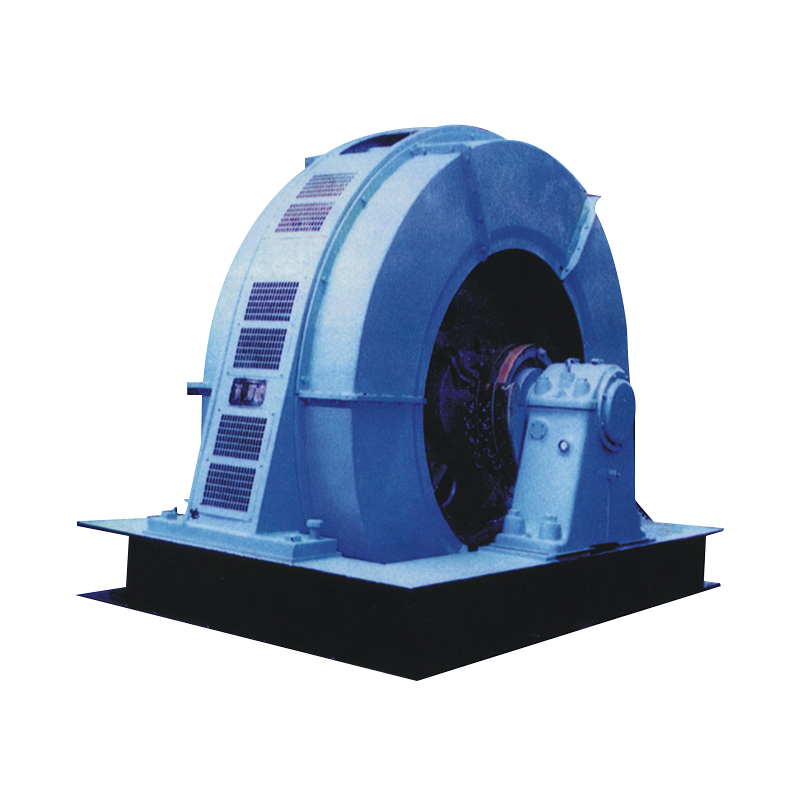

Introduction to High‑Voltage Synchronous Motors

High‑Voltage Synchronous Motors operate by maintaining a constant rotor speed synchronized with the frequency of the electrical supply, making them distinct from induction motors where rotor speed varies with load. Industries such as power generation, petrochemical processing, and large manufacturing plants rely on these motors to deliver consistent performance under heavy loads and extended duty cycles.

Key Advantages of High‑Voltage Synchronous Motors

Efficiency and Energy Savings

One of the most compelling reasons engineers specify High‑Voltage Synchronous Motors is their high efficiency at rated load. Compared with induction motors and other motor types, these synchronous machines can achieve higher efficiencies due to reduced rotor losses and improved power factor characteristics.

| Attribute | High‑Voltage Synchronous Motors | Induction Motors |

| Typical Efficiency | 97%–99%+ | 95%–97% |

| Power Factor | Near unity (0.95–1.0) | 0.85–0.95 |

| Rotor Losses | Lower | Higher |

Improved efficiency translates into reduced electrical losses and lower operational costs over time, which is critical for heavy industrial processes. According to market research, the global high‑voltage motor market was valued at around USD 5.2 billion in 2024 and is expected to grow significantly due to energy efficiency demands in power and manufacturing sectors.

Controllable Power Factor

Unlike asynchronous motor designs, High‑Voltage Synchronous Motors can operate with a controllable power factor, allowing engineers to tune them for specific system requirements. This capability helps reduce reactive power draw from the grid, improving overall plant power quality and reducing utility penalties.

Reliability and Longevity in Heavy Duty Environments

These motors are designed for continuous industrial duty and deliver excellent reliability. Their robust mechanical construction and optimized winding design result in stable performance over long operating hours, reducing unplanned downtime and lifecycle cost.

Applications of High‑Voltage Synchronous Motors

The advantages described above make High‑Voltage Synchronous Motors advantages and applications particularly attractive in sectors where performance, efficiency, and power stability are paramount. Key applications include:

- Power generation and grid support

- Pumps and compressors in petrochemical facilities

- Heavy industrial drives in mining and steel production

- Marine propulsion and large HVAC systems

How to Select High‑Voltage Synchronous Motors for Industrial Use

Choosing the right motor requires balancing technical performance with economic and operational needs. Here are fundamental considerations when selecting High‑Voltage Synchronous Motors for industrial use:

- Voltage Rating – Ensure compatibility with plant electrical distribution levels (e.g., 6kV, 10kV, or higher).

- Load Characteristics – Match the motor shaft power and torque profile to actual process requirements.

- Duty Cycle – Evaluate continuous vs. intermittent duty to size cooling and insulation systems appropriately.

- Efficiency & Power Factor – Select models that meet or exceed current regional energy standards.

Best Maintenance Practices for High‑Voltage Synchronous Motors

Effective maintenance is essential for maximizing the lifecycle and uptime of high‑voltage motors. Recommended strategies include:

- Routine inspection of bearings, windings, and insulation resistance.

- Thermal imaging to detect hotspots and premature wear.

- Alignment and vibration analysis to prevent mechanical stress.

- Lubrication schedules tailored to operating conditions.

Following structured practices helps reduce unexpected failures and extends the service life of the equipment.

Troubleshooting Common Issues in High‑Voltage Synchronous Motors

Identifying and addressing operational issues early can prevent costly downtime. Typical issues include:

- Overheating – Often caused by excessive load or poor cooling airflow.

- Vibration – Imbalance, misalignment, or bearing wear can lead to elevated vibration levels.

- Insulation Degradation – Moisture or contamination can reduce insulation resistance, leading to electrical faults.

Industry Standards and Efficiency Regulations

Recent updates in efficiency standards reflect the industry’s push for energy conservation. International trends, such as the adoption of IEC efficiency classes up to IE5, influence design expectations for high‑voltage motors. While synchronous motors are often exempt from some mid‑range motor mandates, achieving high efficiency levels remains a core engineering objective to align with regulatory and sustainability targets.

Conclusion

In summary, High‑Voltage Synchronous Motors offer significant advantages in efficiency, controllable power factor, and operational reliability. When engineered and maintained correctly, these motors can deliver exceptional performance across demanding industrial environments. By understanding how to select, operate, and troubleshoot these machines, engineers and procurement professionals can optimize system efficiency and long‑term value.

Frequently Asked Questions (FAQ)

- What makes high‑voltage synchronous motors more efficient than other motor types? – Their reduced rotor losses and synchronized rotor speed deliver higher energy conversion efficiency.

- Can high‑voltage synchronous motors improve plant power factor? – Yes, they can be tuned to operate at a near‑unity power factor.

- What industries benefit most from high‑voltage synchronous motors? – Power generation, petrochemicals, mining, and heavy manufacturing are primary sectors.

- How often should maintenance be performed on these motors? – Regularly aligned with usage intensity, typically quarterly or semi‑annually, with condition‑based checks.

- Do industry efficiency standards apply to high‑voltage synchronous motors? – Yes, while some standards focus on low/medium voltage motors, achieving high efficiency is still essential.

English

English русский

русский Français

Français عربى

عربى