What Defines a Reliable Custom Three Phase Wound Rotor Motor?

Understanding the Core Functionality of Custom Three Phase Wound Rotor Motors

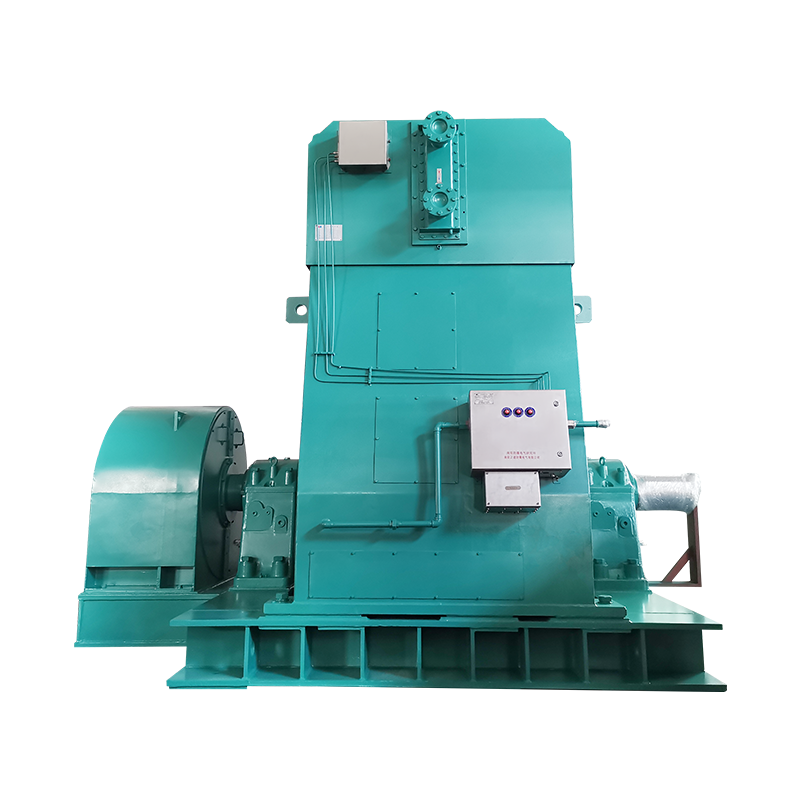

Custom Three Phase Wound Rotor Motors are engineered for applications requiring precise control, high starting torque, and superior adaptability under fluctuating load conditions. These motors use a wound rotor connected through slip rings, enabling the integration of external resistance to optimize torque, speed, and current during startup and operation. Their design makes them indispensable in heavy industries where performance stability and operational flexibility are priorities.

This section also aligns with strategic long-tail keyword integration, including adjustable speed wound rotor motors and high torque three phase wound rotor motors, embedding contextual depth for holistic SEO coverage. Their operational advantages extend into mining, pumping systems, mills, cranes, and environments requiring continuous torque regulation. Below is a concise look at the main performance characteristics:

- Enhanced torque control for demanding mechanical loads

- Ability to adjust resistance externally for optimized starting currents

- Durable performance in harsh industrial environments

- Stable thermal and mechanical structure for long-term reliability

Performance Comparison: Wound Rotor vs Standard Induction Motors

Choosing between a wound rotor motor and a standard induction motor depends largely on required startup behavior, operational control, and load fluctuation tolerance. While induction motors offer simplicity and cost advantages, wound rotor motors deliver optimized torque, adjustable slip characteristics, and reduced mechanical stress during startup—especially valuable for large-scale industrial systems.

| Motor Type | Startup Torque | Speed Control | Maintenance Complexity |

| Wound Rotor Motor | High | Adjustable via external resistance | Moderate |

| Squirrel Cage Induction Motor | Medium | Limited | Low |

Why Industries Require high torque three phase wound rotor motors for Heavy Loads

Industries involving crushers, conveyors, compressors, and large pumps rely on high torque three phase wound rotor motors because these systems demand a controlled increase in torque during startup. A conventional motor may draw excessively high current during this phase, risking grid instability and mechanical strain. By contrast, wound rotor configurations allow external resistances to be progressively reduced, offering both mechanical protection and electrical efficiency.

This feature also aligns with the functionality of industrial wound rotor motor customization, enabling precise calibration according to load profile, voltage environment, duty cycle, and thermal considerations. Below are key industrial benefits:

- Reduced inrush current prevents system disturbances

- Higher reliability under repeated start-stop operations

- Better adhesion to grid capacity limitations

- Improved energy optimization through controlled slip

Application Suitability Matrix

To determine suitability, engineers often examine variables such as startup conditions, mechanical inertia load, torque control requirements, and environmental risk factors. The matrix below outlines typical industrial use cases:

| Application | Load Type | Recommended Motor |

| Mining Conveyors | Variable, heavy | Wound Rotor Motor |

| Fans and Blowers | Light to medium | Induction Motor |

| Crushers and Mills | High inertia | Wound Rotor Motor |

How adjustable speed wound rotor motors Improve Operational Efficiency

One of the primary advantages of adjustable speed wound rotor motors lies in their ability to maintain energy-efficient performance across diverse operational phases. Rather than relying solely on VFD systems—which may be cost-intensive at high power levels—wound rotor motors allow slip energy control via resistance banks. This ensures smoother transitions, minimized vibration, and reduced wear on mechanical parts.

Modern engineering also leverages resistance-based speed control to extend motor lifespan, improve safety margins, and support load-driven speed adjustments without complex electronic hardware. Key performance enhancements include:

- Extended bearing and winding lifespan due to controlled acceleration

- Superior adaptability to high-inertia load transitions

- Lower operational stress during peak demand

- Opportunities for hybrid control systems combining mechanical and electromechanical regulation

Efficiency Comparison Chart

Below is a simplified comparison of operational efficiency under variable loads:

| Motor Setup | Efficiency at Low Load | Efficiency at High Load |

| Induction Motor + VFD | High | High |

| Wound Rotor Motor + Resistance Control | Medium | High |

FAQ

What makes Custom Three Phase Wound Rotor Motors ideal for high-inertia applications?

Their ability to introduce external resistance during startup greatly reduces mechanical stress and electrical surge, making them ideal for heavy-duty applications such as mills, crushers, and large conveyors that require smooth torque buildup.

Are adjustable speed wound rotor motors more efficient than motors using VFDs?

While VFDs can offer higher precision, wound rotor motors provide cost-effective speed control for high-power industrial applications. Their resistance-based regulation minimizes hardware costs and supports robust long-term performance.

How long can a high torque three phase wound rotor motor operate continuously?

With proper cooling and resistance calibration, these motors can run continuously for extended durations under heavy loads. They are engineered with reinforced insulation, thermal protection systems, and advanced winding structures to support demanding duty cycles.

Can wound rotor motors reduce peak current draw?

Yes. By integrating external rotor resistances during startup, wound rotor motors significantly lower inrush currents, protecting the grid and reducing disturbances across the power distribution system.

Are industrial wound rotor motor customization services necessary?

In many settings, yes. Customization ensures that torque curves, coil configurations, insulation grades, and load-matching settings are optimized for specific industrial tasks. This leads to higher efficiency, reduced wear, and improved operational reliability.

English

English русский

русский Français

Français عربى

عربى