What is Y2 Series High-Voltage Three-Phase Induction Motor?

1. Introduction: Why is the Y2 Series High-Voltage Three-Phase Induction Motor So Crucial in Industry?

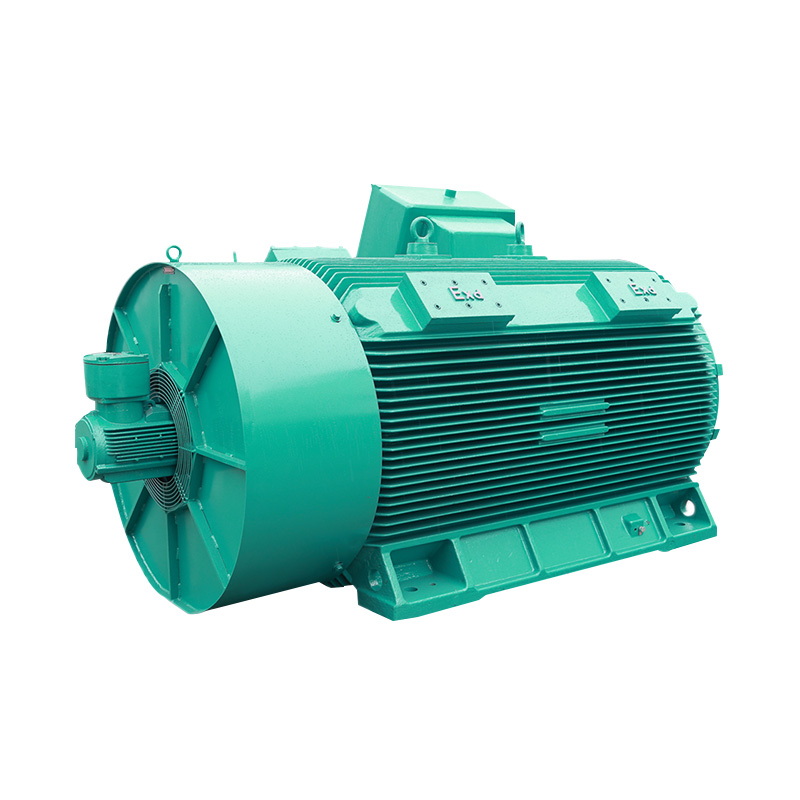

The Y2 series high-voltage three-phase induction motor represents a cornerstone of modern industrial infrastructure. Its paramount importance stems from its direct role in powering the core machinery that drives essential processes. From pumping water and circulating air in HVAC systems to operating compressors, crushers, and conveyor systems, this motor is the workhorse behind countless applications.

Its significance is further amplified by its design, which prioritizes reliability, energy efficiency, and robust performance under demanding conditions. By converting electrical energy into mechanical power with high efficacy, the Y2 series motor ensures operational continuity and productivity. Its widespread adoption across sectors like manufacturing, mining, and water treatment underscores its indispensable position as a critical component in keeping industries running smoothly and efficiently.

2. What is the Y2 Series High-Voltage Three-Phase Induction Motor?

At its core, the Y2 series high-voltage three-phase induction motor is an optimized and standardized line of electric motors designed for operation on three-phase alternating current (AC) power supplies at voltages typically ranging from 3kV to 10kV. The "Y2" designation signifies a specific, modernized generation ("2") within a broader family of industrial motors, indicating advancements in design, materials, and performance over its predecessors. To fully understand what it is, let's break down its key components:

- High-Voltage: This refers to the motor's operating voltage, which is significantly higher than that of standard low-voltage motors (e.g., 380V or 480V). Operating at high voltage (e.g., 6kV or 10kV) is crucial for high-power applications because it reduces the current for the same power output. This reduction in current leads to lower energy losses in the cabling, improves overall system efficiency, and allows for the use of smaller, more economical conductors for power distribution over long distances within an industrial plant.

- Three-Phase: This denotes the type of electrical power supply the motor is built for. Three-phase AC power is the global standard for industrial and commercial power distribution due to its exceptional efficiency and reliability. It produces a rotating magnetic field in a smooth and consistent manner, which allows the motor to start on its own without needing an external starter capacitor and to run with high torque and stable performance.

- Induction Motor (Asynchronous Motor): This defines the fundamental working principle. In an induction motor, the rotor (the rotating part) does not receive electrical power directly. Instead, it is "induced" with electrical currents by the rotating magnetic field created by the stator (the stationary part). This "induction" action is what causes the rotor to turn. This design is renowned for its robustness, simplicity, low maintenance needs, and exceptional durability, as it eliminates the need for physical electrical contacts like brushes and commutators, which are prone to wear and failure.

The "Y2 Series" itself represents a collection of motors built to specific, unified technical standards. This standardization ensures consistent performance characteristics, dimensions, and mounting configurations across different manufacturers, facilitating easier selection, interchangeability, and replacement in industrial settings. It often incorporates improved insulation systems (e.g., Class F or higher), better cooling designs, and optimized electromagnetic calculations to achieve higher efficiency and reliability compared to earlier series like the Y series.

Key Design Evolution: Y Series vs. Y2 Series

While the basic operating principle remains the same, the Y2 series introduced several key improvements over the foundational Y series. The following table outlines the core distinctions that define the Y2 series as a more advanced product line.

| Feature | Y Series (Basic Design) | Y2 Series (Modernized Design) |

|---|---|---|

| Insulation System & Thermal Withstand | Typically utilizes Class B insulation with a lower temperature rating (e.g., 130°C). | Commonly employs Class F insulation (with a Class B temperature rise), rated for higher temperatures (e.g., 155°C). This provides a greater safety margin, enhances thermal durability, and extends the motor's operational lifespan. |

| Electromagnetic Design & Performance | Features a standard electromagnetic design, which may result in higher inrush currents and lower overall efficiency. | Incorporates optimized electromagnetic calculations. This leads to reduced no-load losses, lower starting current, improved full-load power factor, and ultimately, higher operational efficiency. |

| Cooling & Ventilation | Often uses a basic self-ventilation (IC 411) system with a fan cover. | Continues with IC 411 cooling but with potentially optimized fan and airflow designs to work in harmony with the lower heat generation from improved efficiency. |

| Protection Degree (IP Code) | Commonly offers a standard degree of protection, such as IP44 or IP54. | Frequently designed with a higher degree of protection, with IP55 being a common standard. This provides superior defense against dust and water jets, making it suitable for harsher industrial environments. |

| Noise & Vibration Levels | May exhibit higher audible noise and vibration levels due to its foundational design. | Implements design enhancements aimed at reducing vibration and acoustic noise, contributing to a better working environment and potentially longer bearing life. |

In summary, the Y2 series high-voltage three-phase induction motor is not merely a motor; it is a technologically evolved industrial component. It builds upon the proven, rugged principle of induction but refines it with modern materials and engineering to deliver greater efficiency, reliability, and durability, making it a superior choice for a vast array of heavy-duty industrial applications.

3. What are the Key Features and Advantages of the Y2 Series High-Voltage Motor?

The Y2 series high-voltage three-phase induction motor is not just a successor to previous models; it is a comprehensive upgrade engineered to deliver superior performance, reliability, and operational economy. Its key features are intricately designed to address the core demands of industrial applications: minimizing downtime, reducing operating costs, and withstanding challenging environments. The advantages it offers become clear when its features are compared directly with the foundational standards of earlier generations.

Core Features and Comparative Advantages

The following table delineates the specific technological advancements of the Y2 series and contrasts them with the typical characteristics of basic high-voltage motor designs to highlight its tangible benefits.

| Key Feature | Implementation in Y2 Series | Comparative Advantage & Benefit |

|---|---|---|

| High-Efficiency Design | Utilizes optimized core laminations, reduced air gap, precision-machined copper rotor bars, and improved winding techniques to minimize electrical, magnetic, and mechanical losses. | Significantly Lower Operating Costs: Achieves higher efficiency levels (e.g., meeting or exceeding IE2/IE3 efficiency classes). This translates to substantially reduced energy consumption over the motor's operational lifespan, leading to lower electricity bills and a smaller carbon footprint. |

| Enhanced Insulation System | Employs Class F (or higher) insulation materials, often with vacuum pressure impregnation (VPI) treatment, but is designed to operate at a lower temperature rise (typically Class B). | Extended Service Life and Superior Reliability: The high-grade insulation operating at a lower temperature experiences less thermal degradation. This provides a large thermal safety margin, drastically extending the insulation's life and enhancing the motor's ability to handle overload conditions and voltage fluctuations without failure. |

| Robust Protection Degree | Designed with a high degree of ingress protection, with IP55 being a standard specification for most models. | Excellent Suitability for Harsh Environments: The IP55 rating guarantees protection against dust that could harm equipment and against water jets from any direction. This makes the Y2 series ideal for use in dusty, humid, or wet industrial settings like mines, cement plants, and chemical processing facilities, reducing the risk of internal contamination. |

| Advanced Cooling System | Features an optimized internal cooling circuit and an efficient external fan design with an aerodynamically optimized fan cover to maximize airflow and minimize noise. | Improved Thermal Management and Quieter Operation: The enhanced cooling system ensures effective heat dissipation from the core and windings, directly supporting the high-efficiency design and contributing to longer lifespan. Additionally, this results in lower audible noise levels, improving the working environment. |

| Low Vibration & High Precision | Incorporates static and dynamic balancing to high precision standards, coupled with a rigid frame construction. | Smooth Operation and Reduced Mechanical Stress: Low vibration levels lead to smoother performance, less wear on bearings and connected equipment (like pumps and gearboxes), and reduced structural noise. This enhances overall system reliability and reduces maintenance needs for both the motor and the driven machine. |

| Material & Construction Quality | Uses high-quality cast iron for the frame and end brackets, providing superior strength, vibration damping, and corrosion resistance compared to aluminum or lower-grade iron. | Exceptional Durability and Mechanical Robustness: The robust construction ensures the motor can withstand the physical stresses of continuous operation, heavy loads, and demanding start-stop cycles. It is better equipped to handle mechanical shocks and corrosive atmospheres, ensuring long-term structural integrity. |

Synthesis of Advantages

In essence, the key features of the Y2 series high-voltage motor converge to deliver a compelling package of advantages for industrial users. Its high efficiency directly impacts the bottom line through energy savings. The robust insulation and construction maximize uptime and asset life, reducing the total cost of ownership. The high IP protection rating expands its applicability across a wider range of demanding environments, increasing its versatility. Finally, the smooth and quiet operation contributes to a safer and more sustainable plant operation.

Therefore, selecting a Y2 series motor is not merely a choice of a component but an investment in operational resilience, cost-effectiveness, and long-term equipment reliability, making it a technically and economically sound decision for power-intensive industries.

4. How to Read the Technical Parameters of a Y2 Series High-Voltage Motor?

Understanding the nameplate and technical specifications of a Y2 series high-voltage motor is crucial for proper selection, installation, and operation. These parameters are not just arbitrary numbers; they tell the story of the motor's capabilities, limitations, and its fit for a specific application. Misinterpreting them can lead to inefficiency, premature failure, or even safety hazards. This guide will demystify these key parameters, empowering you to make informed decisions.

1. Decoding the Model Number: Y2-315L2-2

The model number is a compact code that reveals fundamental physical and performance characteristics. Let's break down a typical example: Y2-315L2-2.

- Y2: Denotes the series name, indicating it belongs to this modernized, high-efficiency family of motors.

- 315: This is the center height of the motor shaft in millimeters. It is a key indicator of the motor's physical size and power frame. A larger number generally corresponds to a higher power output.

- L2: This is the core length code. Manufacturers use codes like "S" (short), "M" (medium), "L" (long), and sometimes with numbers (L1, L2) to designate different stack lengths of the magnetic core. A longer core typically means more power from the same frame size.

- -2: This final number indicates the number of magnetic poles the motor has. A "2" means it is a 2-pole motor, which will run at a synchronous speed of 3000 RPM (at 50Hz). Other common values are 4 (1500 RPM), 6 (1000 RPM), and 8 (750 RPM).

Therefore, a Y2-315L2-2 is a modernized series motor with a 315mm center height, a long stack (version 2), designed to operate at a high speed (around 2970 RPM under full load).

2. Understanding Core Performance Specifications

Beyond the model number, the detailed technical sheet provides a deeper look into performance. The following table explains the most critical parameters you will encounter.

| Technical Parameter | Explanation & Significance | Why It Matters for Selection |

|---|---|---|

| Rated Voltage | The designated supply voltage for optimal performance (e.g., 6 kV, 10 kV). | The motor must be connected to a power supply that matches this voltage. Operating at a significantly different voltage can cause overheating, torque loss, and insulation damage. |

| Rated Power (kW) | The useful mechanical power the motor can continuously deliver at the shaft without exceeding its temperature limits. | This is the primary parameter for matching the motor to the load. Selecting a motor with too little power for the application will cause it to overload and fail. Oversizing is inefficient and costly. |

| Rated Frequency (Hz) | The frequency of the AC power supply, typically 50 Hz or 60 Hz. | The motor's speed is directly proportional to the supply frequency. Using the wrong frequency will result in incorrect operating speed and potential damage. |

| Rated Current (A) | The current the motor draws from the power supply when delivering its rated power at rated voltage and frequency. | This value is critical for sizing protective devices like circuit breakers and overload relays. A motor drawing more than its rated current is likely overloaded. |

| Rated Speed (RPM) | The rotational speed of the motor under full rated load. It is slightly less than the synchronous speed due to "slip." | Essential for ensuring compatibility with the driven equipment (pump, fan, compressor). The wrong speed can severely impact the system's performance. |

| Efficiency (η) | The ratio of output mechanical power to input electrical power, expressed as a percentage. | A higher efficiency rating (e.g., IE2, IE3) means lower energy losses and reduced electricity costs. This is a key factor in calculating the total cost of ownership. |

| Power Factor (cos φ) | The ratio of real (working) power to apparent (total) power drawn. It indicates how effectively the motor uses the current. | A higher power factor (closer to 1.0) is better, as it reduces the current drawn for the same power output and lessens the burden on the electrical distribution system. |

| Starting Current (Locked-Rotor Current) | The very high current drawn by the motor at the instant it is energized before it begins to rotate. | Expressed as a multiple of the rated current (e.g., 6.5 x Iₙ). This is vital for designing the electrical system to handle the inrush without nuisance tripping. |

| Starting Torque (Locked-Rotor Torque) | The torque the motor produces at zero speed when power is applied. | It must be high enough to overcome the static friction of the load and start it moving. Critical for applications with high breakaway torque, like conveyors loaded with material. |

| Max Torque (Breakdown Torque) | The maximum torque the motor can produce without stalling. | This is a safety margin. It indicates the motor's ability to handle temporary overload conditions (e.g., a sudden jam) without an immediate stop. |

| Protection Degree (IP Code) | A standard code (e.g., IP55) defining the level of protection against solid objects and liquids. | As discussed previously, this determines the suitability for the operating environment (dusty, wet, clean). |

| Insulation Class | Specifies the thermal tolerance of the insulation system (e.g., Class F). | Defines the maximum temperature the insulation can withstand, directly impacting the motor's service life and overload capability. |

Synthesis: Reading the Whole Story

When analyzing a Y2 series motor's parameters, it's essential to view them as an interconnected system. For instance, a motor with a high starting torque might also have a higher starting current. A motor designed for high efficiency might have a slightly higher initial cost but will pay back the difference through energy savings. By cross-referencing these parameters against your application's requirements—such as the load profile, starting conditions, ambient environment, and duty cycle—you can move beyond simply reading numbers to truly understanding the motor's capabilities and ensuring a perfect, reliable match for your needs.

5. Where are Y2 Series High-Voltage Motors Primarily Used?

The Y2 series high-voltage three-phase induction motor is a cornerstone of heavy industry and critical infrastructure. Its design, which emphasizes high power, robustness, and reliable operation under continuous duty cycles, makes it unsuitable for small-scale applications but ideal for driving the most demanding mechanical systems. Its primary use is to convert electrical energy into the rotational mechanical power required to run large-scale pumps, fans, compressors, and other machinery. The following sections and table detail its principal application areas.

Core Application Areas

- Water and Wastewater Treatment: This sector relies heavily on Y2 series motors for critical processes. They are used to drive high-power pumps for raw water intake, transferring treated water across long distances (booster pumps), and handling sludge. Their ability to run continuously for extended periods is essential here. The high IP protection rating (like IP55) is crucial for withstanding humid, and sometimes corrosive, environments in pumping stations.

- Power Generation and HVAC: In thermal power plants, they drive induced draft (ID) and forced draft (FD) fans, crucial for the combustion process. They are also used for boiler feed pumps. In large commercial or industrial complexes, they serve as the prime mover for large cooling tower fans and chilled water pumps in central HVAC systems, where their energy efficiency directly translates to significant operational cost savings.

- Mining and Minerals Processing: The mining industry subjects equipment to extreme conditions, including abrasive dust, mechanical shocks, and continuous heavy loads. Y2 motors power crushers and grinding mills that reduce the size of extracted ore, conveyor systems for transporting material, and ventilation fans for providing fresh air underground. Their robust cast-iron construction and high starting torque are vital in these applications.

- Oil and Gas Industry: In upstream, midstream, and downstream operations, Y2 motors are employed to drive injection pumps for secondary oil recovery, pipeline compressors for transporting natural gas over vast distances, and various pumps within refineries and petrochemical plants. Reliability is paramount in these continuous-process industries, as unplanned downtime results in massive financial losses.

- General Manufacturing and Heavy Machinery: They form the backbone of many production lines, providing power for compressors that generate plant air, hydraulic units, and large machine tools. Furthermore, they are found in specific heavy equipment like extruders in plastic manufacturing and pelletizers in the fertilizer industry.

Application-Specific Motor Characteristics

The table below illustrates how the inherent features of the Y2 series motor align with the demands of different industrial sectors.

| Application Sector | Specific Machinery Examples | Why the Y2 Series is a Suitable Fit |

|---|---|---|

| Water & Wastewater | • Raw Water & Booster Pumps • Sludge Pumps • Circulator Pumps |

• High Efficiency reduces the massive electricity cost of continuous pumping. • IP55 Protection safeguards against moisture and dust. • Robust Construction ensures longevity in damp environments. |

| Power Generation & HVAC | • ID/FD Fans • Boiler Feed Pumps • Cooling Water Pumps & Fans |

• High Reliability prevents costly outages in power generation. • Optimized Cooling System handles continuous operation. • High Starting Torque capable of starting large fan loads. |

| Mining & Minerals | • Crushers & Grinding Mills • Belt Conveyors • Mine Ventilation Fans |

• High Breakdown Torque resists stalling under shock loads (e.g., a jammed crusher). • Durable Cast-Iron Frame withstands vibration and physical abuse. • IP55 Protection is essential to keep out abrasive dust. |

| Oil & Gas | • Pipeline Compressors • Injection Pumps • Refinery Process Pumps |

• Enhanced Insulation System (Class F) provides a safety margin in high-temperature environments. • High Reliability is critical for 24/7 operations where downtime is extremely expensive. • Low Vibration protects connected equipment and piping. |

| General Manufacturing | • Large Air Compressors • Industrial Extruders • Pelletizing Machinery |

• Smooth Operation (Low Vibration) is key for precision manufacturing processes. • Standardized Dimensions (Y2 Series) allow for easy replacement and interoperability. • Versatile Performance across various load and speed requirements. |

In summary, the Y2 series high-voltage motor is the driving force behind a vast swath of modern industrial and infrastructural activity. Its deployment is most prominent in scenarios requiring a combination of high power, exceptional reliability, and energy efficiency for continuous operation. By matching its technical strengths—such as its robust build, high protection rating, and superior torque characteristics—to the specific demands of an application, engineers can ensure optimal performance, minimize lifecycle costs, and achieve maximum operational uptime.

6. How to Select the Right Y2 Series High-Voltage Motor for Your Project?

Selecting the appropriate Y2 series high-voltage motor is a critical engineering decision that goes far beyond simply matching power and speed. A correctly chosen motor will deliver years of reliable, efficient, and cost-effective service, while an improper selection can lead to chronic operational issues, premature failure, and unexpectedly high lifetime costs. This guide provides a systematic approach to ensuring the motor you select is perfectly tailored to your project's specific requirements, focusing on technical and economic factors.

A Step-by-Step Selection Framework

- Define the Load Requirements Precisely: This is the most fundamental step. The motor must be capable of driving the specific load under all expected conditions.

- Power (kW) and Torque Profile: Determine the continuous power required. Crucially, analyze the torque-speed characteristic of the driven equipment. Is it a variable torque load (e.g., centrifugal pumps and fans) where torque increases with speed, or a constant torque load (e.g., conveyors, compressors) requiring high torque even at low speeds?

- Starting Conditions: Assess the breakaway torque needed to start the load. High-inertia loads (like large fans or mills) require a motor with high starting torque.

- Duty Cycle: Define how the motor will be operated. Is it continuous duty (S1), intermittent duty (S3), or something else? A motor for continuous 24/7 operation must be chosen with a robust thermal design.

- Match Technical Specifications to the Load: Using the load analysis from step 1, you can now specify the motor's key performance parameters.

- Rated Power and Speed: Select a motor with a rated power that has a sufficient margin above the load's maximum continuous demand to avoid overloading. Match the motor's rated speed (e.g., 4-pole for ~1480 RPM) to the driven equipment's required operating speed.

- Starting and Maximum Torque: Ensure the motor's starting torque (locked-rotor torque) exceeds the load's breakaway torque. Verify that the motor's maximum (breakdown) torque is higher than any potential peak load to prevent stalling.

- Voltage and Frequency: Confirm the motor's rated voltage and frequency (e.g., 6 kV, 50 Hz) match your plant's electrical supply.

- Evaluate the Operating Environment: The installation location dictates necessary motor features for reliability.

- Ambient Temperature: High ambient temperatures may require a motor with a higher insulation class (e.g., Class F or H) to maintain a safe operating temperature.

- Surroundings: In the presence of dust, moisture, or corrosive gases, a high Ingress Protection (IP) code like IP55 or even IP65 is non-negotiable. For hazardous areas with flammable gases or dust, an explosion-proof certification (like ATEX or IECEx) is required, which is a separate specialization from the standard Y2 series.

- Altitude: Operation at high altitudes (above 1000 meters) reduces the effectiveness of air cooling and may require a motor derating or a special design.

- Analyze Performance and Economic Factors: This step moves beyond basic functionality to optimize total cost of ownership.

- Efficiency Class: Higher efficiency motors (e.g., IE3, IE4) have a higher initial purchase price but consume significantly less electricity. For a motor running thousands of hours per year, the energy savings can quickly offset the higher upfront cost.

- Power Factor: A higher native power factor reduces the reactive power drawn from the grid, which can avoid utility penalties and reduce the sizing requirements for power factor correction equipment.

Decision Matrix: Key Selection Criteria

The following table summarizes the critical parameters and how your project's requirements should guide your choice.

| Selection Criterion | Project Requirement & Its Impact on Motor Choice | Key Question to Ask |

|---|---|---|

| Rated Power & Speed | The load's power consumption and desired operating RPM. An undersized motor will fail; an oversized one is inefficient. | "What is the maximum continuous mechanical power (kW) and speed (RPM) my equipment requires?" |

| Torque Profile | The load's inherent characteristic (Constant Torque vs. Variable Torque) and starting inertia. | "Does my application require very high torque to start (like a conveyor), or is the starting load low (like a pump)?" |

| Duty Cycle & Environment | How long and how hard the motor will run, and in what conditions. | "Will the motor run 24/7, and is it installed in a clean room, a dusty mine, or a humid pit?" |

| Efficiency Class (e.g., IE2/IE3) | The annual operating hours and local electricity cost. | "Given our energy prices and runtime, will the long-term savings of a premium-efficiency (IE3) motor justify its higher initial cost compared to a standard-efficiency (IE2) model?" |

| Protection Degree (IP Code) | The level of exposure to solid objects and liquids. | "Do I need a standard IP23 for a clean, indoor motor control center, or is an IP55 rating essential for wash-down or dusty areas?" |

| Supply Voltage & Frequency | The available plant electrical system. | "Does our facility use a 6 kV or 10 kV distribution system, and is it 50 Hz or 60 Hz?" |

| Cooling Method | The available space for ventilation and ambient cooling conditions. | "Is a standard fan-cooled (IC 411) design sufficient, or do we need a more advanced cooling system for a confined space?" |

The Concept of Total Cost of Ownership (TCO)

A prudent selection process must look beyond the initial purchase price. The Total Cost of Ownership for an industrial motor is a more accurate measure of its economic impact. TCO is calculated as:

TCO = Initial Purchase Price + (Energy Cost over Lifetime) + Maintenance Costs + Downtime Costs

A higher-efficiency Y2 series motor, while potentially 15-30% more expensive to purchase than a standard-efficiency model, can often have a lower TCO because the energy cost component—which can account for over 95% of the TCO—is drastically reduced. Therefore, the "cheapest" motor on the price tag is often the most expensive one to own and operate over a decade.

By meticulously following this framework and using the decision matrix, you can transform the motor selection process from a simple parts procurement task into a strategic engineering and financial decision, ensuring your project benefits from optimal performance, maximum reliability, and the lowest possible lifetime cost.

7. Conclusion

In summary, the Y2 series high-voltage three-phase induction motor stands as a testament to modern electromechanical engineering, offering a blend of robustness, efficiency, and adaptability that makes it a cornerstone of industrial infrastructure. Throughout this analysis, we have deconstructed its core identity, moving beyond a simple component to understanding it as a sophisticated system. Its significance is rooted in a design philosophy that prioritizes operational longevity and cost-effectiveness, achieved through advancements in insulation materials, electromagnetic design, cooling mechanisms, and structural integrity.

The key to unlocking the full value of the Y2 series lies in a meticulous and informed selection process. It is not a one-size-fits-all product but a versatile platform whose specific configuration must be carefully matched to the application's demands. This involves a deep understanding of load characteristics—be it the constant torque of a conveyor or the variable torque of a pump—as well as the environmental challenges and economic considerations of the project. The following table provides a final, consolidated overview of the primary value propositions of the Y2 series, synthesizing the technical details discussed in earlier sections into a clear strategic rationale for its selection.

| Value Proposition | Technical & Economic Rationale | Long-Term Impact |

|---|---|---|

| Superior Operational Reliability & Uptime | • Class F Insulation (with Class B rise): Provides a significant thermal safety margin, drastically reducing insulation degradation over time. • Robust Cast-Iron Construction: Offers excellent vibration damping and resistance to mechanical stress and corrosion. • High Protection Degree (IP55): Ensures internal components are shielded from dust and moisture, a common cause of failure. |

Maximizes production availability and minimizes unplanned downtime, which is often far more costly than the motor itself. This translates to higher plant throughput and operational stability. |

| Enhanced Energy Efficiency & Cost Savings | • Optimized Electromagnetic Design: Reduces stator and rotor losses, leading to higher efficiency classes (IE2/IE3). • Lower Losses: Directly convert to reduced heat generation, which in turn lowers cooling demands and further improves efficiency. |

Drastically lowers the total cost of ownership (TCO). The initial investment in a high-efficiency model is quickly offset by substantial reductions in electricity consumption over the motor's operational lifespan. |

| Adaptability to Demanding Environments | • Standard IP55 Rating: Makes it suitable for harsh settings like mining, wastewater treatment, and cement plants. • Rigorous Balancing: Results in low vibration levels, protecting both the motor and the driven equipment. • High Torque Capabilities: Ensures reliable starting and operation under heavy loads and potential overload conditions. |

Provides a single, reliable solution for a wide array of industries, simplifying procurement and inventory management while ensuring performance integrity across diverse operational challenges. |

| Informed & Strategic Selection | The comprehensive technical parameter set (power, speed, torque, IP code, efficiency) allows for precise engineering matching to the application, avoiding the pitfalls of both under-sizing and over-sizing. | Ensures optimal system performance, prevents premature failure due to misapplication, and guarantees that the selected motor delivers the intended return on investment by performing its specific duty with maximum efficacy. |

Ultimately, selecting a Y2 series high-voltage motor is an investment in operational excellence. It is a decision that prioritizes long-term performance and economy over short-term acquisition cost. By leveraging its advanced design features—from its thermal resilience to its energy-saving potential—and by applying a rigorous selection process that aligns its capabilities with specific project needs, engineers and operators can ensure the continued efficiency, reliability, and productivity of the critical systems that power our industries. The Y2 series, therefore, is more than just a motor; it is a foundational element for building a more resilient and cost-effective industrial operation.

Frequently Asked Questions (FAQ)

- What is the fundamental difference between a standard Y series and the Y2 series motor?

The difference is a generational technological upgrade. The Y2 series is not a simple iteration but a comprehensive enhancement over the basic Y series. Key improvements include the use of a Class F insulation system (often operated at a Class B temperature rise) for a greater thermal safety margin and longer life, optimized electromagnetic design for higher efficiency and lower operating costs, and a typically higher standard IP55 protection rating for superior defense against dust and water, making it suitable for harsher environments. - For a new project, how do I decide between an IE2 and an IE3 efficiency class for a Y2 series motor?

The choice should be based on a Total Cost of Ownership (TCO) analysis. While an IE3 motor has a higher initial purchase price, it consumes less electricity. Calculate the annual energy savings based on your local electricity cost and the motor's expected annual operating hours. For a motor that runs continuously, the energy savings of an IE3 model will often pay back the price premium in a short period, making it the more economical choice over its entire lifespan. If the motor is used only intermittently, the payback period may be longer. - Can a Y2 series motor be used to directly replace an older, existing high-voltage motor?

It can be a suitable replacement, but a direct "drop-in" replacement is not guaranteed and requires careful verification. You must check several key parameters:- Physical Dimensions: Confirm the foot-mounting dimensions, shaft height, and shaft diameter match.

- Electrical Characteristics: Ensure the rated voltage, frequency, and power are identical.

- Performance Match: Verify that the new motor's starting torque and speed meet the requirements of the driven equipment.

- Connections: Check that the terminal box configuration and cable termination system are compatible.

English

English русский

русский Français

Français عربى

عربى