YKS Series High-Voltage Three-Phase Induction Motor: What Makes it Special?

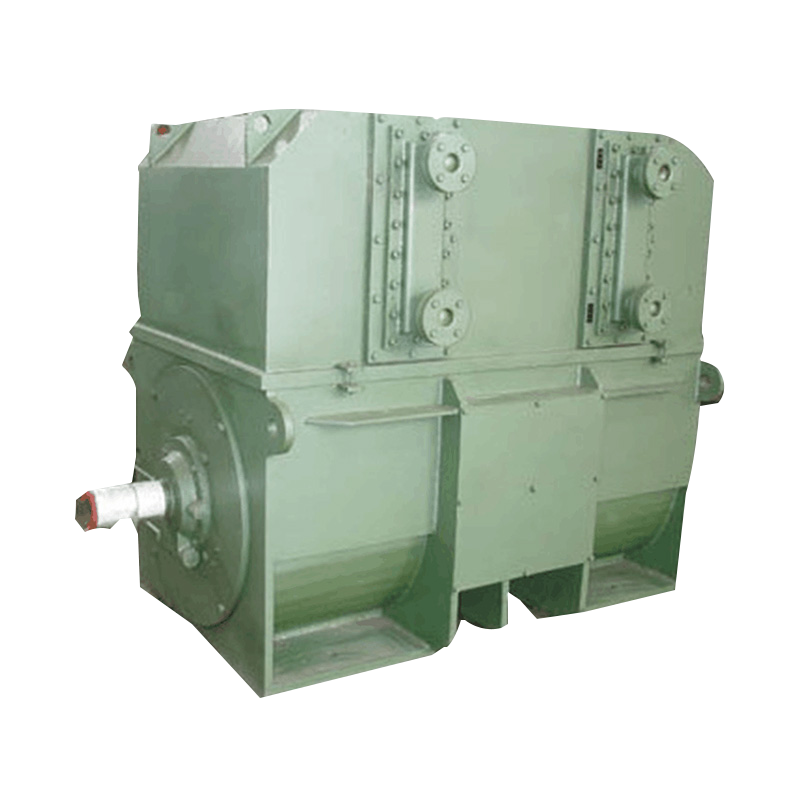

What is the YKS Series High-Voltage Three-Phase Induction Motor?

The YKS Series High-Voltage Three-Phase Induction Motor is a type of electrical machine designed to operate efficiently under high-voltage conditions. It converts electrical energy into mechanical energy using electromagnetic induction, making it suitable for heavy-duty industrial applications. Its three-phase design ensures balanced power distribution and stable performance, even under demanding workloads.

Why is it Popular in the Industrial Field?

This motor is widely favored in industrial settings due to its reliability, durability, and ability to handle high power loads. It offers high efficiency, low maintenance requirements, and excellent thermal management, which are critical for continuous operation in factories, power plants, and large-scale manufacturing facilities. Its robust construction and adaptability to various applications make it a preferred choice for engineers and industrial operators.

1. How is it Different from a Regular Three-Phase Induction Motor?

The YKS Series High-Voltage Three-Phase Induction Motor is an advanced type of induction motor specifically engineered to meet the demands of high-voltage industrial applications. While both YKS motors and standard three-phase induction motors operate on the same fundamental principles of electromagnetic induction, there are several key differences in their design, performance, and suitability for heavy-duty environments.

Fundamental Principles

Like all three-phase induction motors, the YKS Series converts electrical energy into mechanical energy through the interaction of a rotating magnetic field in the stator and induced currents in the rotor. This design allows for smooth torque generation and reliable operation under continuous load. However, the YKS Series is optimized to handle higher voltages and larger loads without compromising efficiency or longevity.

Design and Construction Differences

- Insulation and Voltage Rating: The YKS Series is built with high-grade insulation materials that allow it to operate at significantly higher voltages than a standard induction motor, reducing the risk of electrical breakdown.

- Rotor Structure: While standard three-phase induction motors often use conventional rotor bars, the YKS Series may feature reinforced rotor designs to improve mechanical strength and reduce vibrations at high load conditions.

- Cooling System: Many YKS motors include advanced cooling methods, such as water cooling or enhanced air circulation, which maintain optimal operating temperatures even under continuous high-power operation.

- Efficiency and Performance: The YKS Series achieves higher efficiency levels, especially under heavy load conditions, which translates into lower energy consumption and reduced operational costs over time.

Parameter Comparison Table

| Feature | YKS Series High-Voltage Motor | Standard Three-Phase Induction Motor |

|---|---|---|

| Voltage Rating | 3 kV – 13.8 kV | 380 V – 690 V |

| Power Output | 500 kW – 10 MW | 1 kW – 500 kW |

| Cooling System | Advanced water or air cooling | Standard air cooling |

| Efficiency | 95% – 97% | 85% – 92% |

| Insulation Class | Class F or H | Class B or F |

| Suitable Load | Continuous heavy industrial loads | Moderate industrial loads |

| Rotor Design | Reinforced rotor bars, low vibration | Standard rotor bars |

Applications

- High-capacity pumps, compressors, and industrial mills

- Heavy-duty fans and ventilation systems

- Mining and metallurgical machinery

Summary

While the core working principle of both motors is similar, the YKS Series High-Voltage Three-Phase Induction Motor stands out for its ability to handle higher voltages, heavier loads, and more demanding industrial conditions. Its advanced design, higher efficiency, and robust construction make it a superior choice in industries that require continuous, reliable, and high-performance electrical machinery.

2. Why Choose a High-Voltage Asynchronous Motor?

High-voltage asynchronous motors, such as the YKS Series, are widely used in industrial applications due to their unique advantages over low-voltage or standard induction motors. These motors are designed to operate efficiently under high voltage conditions, providing increased power output, stability, and reliability in demanding environments.

Key Advantages of High-Voltage Asynchronous Motors

- High Power Capacity: Can handle significantly larger loads than standard motors, suitable for heavy machinery, large pumps, compressors, and industrial mills.

- Energy Efficiency: Operating at higher voltage reduces current for the same power output, lowering energy losses and improving efficiency.

- Improved Reliability: Robust insulation, reinforced rotor, and enhanced cooling systems allow continuous heavy-load operation without overheating.

- Reduced Transmission Losses: Minimizes voltage drops in long-distance power transmission within industrial plants.

- Longer Service Life: Superior construction and lower operating currents reduce wear, extend operational life, and reduce maintenance.

Comparison Table: High-Voltage vs. Standard Motors

| Feature | High-Voltage Asynchronous Motor | Standard Three-Phase Motor |

|---|---|---|

| Voltage Rating | 3 kV – 13.8 kV | 380 V – 690 V |

| Maximum Power | 500 kW – 10 MW | 1 kW – 500 kW |

| Current | Lower for same power | Higher for same power |

| Efficiency | 95% – 97% | 85% – 92% |

| Thermal Management | Advanced cooling (water/air) | Standard air cooling |

| Operational Reliability | Very high under heavy load | Moderate under heavy load |

| Maintenance Frequency | Low | Higher |

| Application Scope | Heavy-duty industrial operations | Light to medium industrial use |

Industrial Applications

- Steel mills and rolling machines

- Large pumps and compressors in chemical plants

- Mining and mineral processing equipment

- Water treatment plants with high-capacity pumps

- Heavy-duty fans and ventilation systems

Summary

Choosing a high-voltage asynchronous motor ensures superior performance, higher efficiency, and longer operational life in demanding industrial environments. While standard three-phase motors may be sufficient for small to medium operations, the YKS Series High-Voltage Three-Phase Induction Motor is the optimal solution for industries requiring continuous high-power operation with minimal downtime.

3. Is it a Water-Cooled Motor? Why is it Important?

The YKS Series High-Voltage Three-Phase Induction Motor often features water cooling, which is a critical factor for maintaining performance and reliability in high-power industrial applications. While standard motors typically rely on air cooling, water-cooled systems offer superior thermal management, enabling the motor to operate under continuous heavy loads without overheating.

How Water Cooling Works

Water-cooled motors circulate coolant through channels or jackets around the stator and rotor. The water absorbs heat generated during motor operation and transfers it to an external heat exchanger. This efficient heat removal prevents the motor from exceeding safe temperature limits, protecting insulation and internal components from damage.

Advantages of Water-Cooled Motors

- Better Thermal Management: Maintains a lower and more stable operating temperature, increasing efficiency and prolonging motor life.

- Higher Power Density: Allows higher power outputs in the same physical size compared to air-cooled motors.

- Reduced Noise and Vibration: Absorbs some mechanical vibrations and noise, resulting in quieter operation.

- Longer Lifespan: Lower operating temperatures reduce stress on insulation and bearings.

- Consistent Performance in Harsh Environments: Reliable operation even in high ambient temperatures or limited airflow.

Comparison Table: Water-Cooled vs. Air-Cooled Motors

| Feature | Water-Cooled Motor | Air-Cooled Motor |

|---|---|---|

| Cooling Medium | Water or liquid coolant | Air |

| Heat Dissipation | High efficiency | Moderate efficiency |

| Operating Temperature | Lower and stable | Higher, fluctuates with ambient conditions |

| Power Density | High | Moderate |

| Noise Level | Low | Moderate to high |

| Maintenance | Periodic coolant check | Regular cleaning of cooling fins |

| Suitability | Heavy-duty continuous operation | Light to medium load applications |

| Lifespan | Longer | Shorter under high load |

Applications of Water-Cooled Motors

- Large compressors and pumps

- Steel rolling mills and heavy-duty conveyors

- Mining equipment under continuous operation

- High-capacity fans in power plants

Summary

Water cooling is an essential feature for high-voltage, high-power motors like the YKS Series. It ensures stable operation under heavy loads, improves efficiency, reduces noise, and extends service life. For industries requiring continuous operation at high power levels, water-cooled motors provide significant advantages over standard air-cooled motors.

4. Is it a Squirrel Cage Motor? What Are the Benefits?

The YKS Series High-Voltage Three-Phase Induction Motor typically features a squirrel cage rotor, which is one of the most widely used rotor designs in industrial induction motors. The squirrel cage design is renowned for its simplicity, durability, and reliability, making it ideal for heavy-duty industrial applications.

How the Squirrel Cage Rotor Works

In a squirrel cage motor, the rotor consists of conductive bars embedded in a cylindrical iron core and short-circuited at both ends by end rings. When a three-phase current flows through the stator, it generates a rotating magnetic field, which induces a current in the rotor bars. This induced current produces a secondary magnetic field that interacts with the stator field, creating torque and causing the rotor to spin.

Advantages of Squirrel Cage Motors

- Robust and Reliable: The simple rotor construction has no brushes or slip rings, reducing maintenance requirements and potential points of failure.

- High Efficiency: Highly efficient under continuous heavy loads, ideal for industrial applications.

- Low Maintenance: Requires minimal maintenance over service life due to absence of brushes and complex components.

- Good Starting Performance: Provides high starting torque, suitable for pumps, compressors, and conveyors.

- Durable in Harsh Conditions: Solid rotor construction allows operation in dusty, humid, or vibrating environments without damage.

Comparison Table: Squirrel Cage vs. Wound Rotor Motors

| Feature | Squirrel Cage Motor | Wound Rotor Motor |

|---|---|---|

| Rotor Type | Solid bars with end rings | Wound coils connected through slip rings |

| Starting Torque | Moderate to high | Adjustable, high starting torque possible |

| Efficiency | High | Moderate, slightly lower than squirrel cage |

| Maintenance | Low | Higher, requires brush and slip ring upkeep |

| Reliability | Very high | Moderate |

| Complexity | Simple | Complex |

| Suitable Applications | Pumps, fans, compressors, industrial mills | Heavy-load machinery needing controlled start |

Applications of Squirrel Cage Motors

- Large industrial fans and blowers

- Pumps and compressors in chemical and water treatment plants

- Conveyors and material handling equipment

- Mining and metallurgical machinery

Summary

The squirrel cage design is a defining feature of the YKS Series High-Voltage Three-Phase Induction Motor, offering robustness, efficiency, and minimal maintenance. This design makes it highly suitable for heavy-duty industrial applications, ensuring consistent performance even in challenging operational environments.

5. Does it Comply with IEC Standards? Why is it Important?

The YKS Series High-Voltage Three-Phase Induction Motor is designed to comply with IEC (International Electrotechnical Commission) standards, which are globally recognized guidelines for electrical machinery. Compliance with these standards ensures safety, reliability, efficiency, and interoperability in industrial applications.

Why IEC Standards Matter

- Safety Assurance: IEC standards set limits for insulation, temperature rise, and mechanical stress, reducing the risk of motor failure or accidents during operation.

- Global Compatibility: Motors designed according to IEC standards can be integrated into systems worldwide without compatibility issues.

- Performance Consistency: IEC standards define criteria for efficiency, power factor, and thermal management, ensuring consistent performance under various load conditions.

- Longevity and Reliability: Following IEC standards ensures robust construction, reducing wear and tear and extending the motor’s service life.

- Regulatory Compliance: Many industrial and governmental regulations require adherence to IEC standards for electrical machinery.

Comparison Table: IEC Standard Requirements vs. YKS Series Features

| Feature | IEC Standard Requirement | YKS Series Feature |

|---|---|---|

| Insulation Class | Minimum Class F for high-voltage motors | Class F or H for extended thermal endurance |

| Temperature Rise | ≤ 80–105°C depending on class | Maintains ≤ 95°C under full load |

| Efficiency | Meets minimum efficiency class IE2/IE3 | Achieves IE3/IE4 efficiency levels |

| Vibration Limits | < 50 µm peak-to-peak at rated speed | < 45 µm with reinforced rotor design |

| Noise Level | Defined limits for industrial motors | Within IEC-specified noise limits, quieter due to water cooling |

| Mechanical Strength | Must withstand rated torque and short-circuit stress | Reinforced casing and rotor bars exceed requirements |

| Testing | Standard factory acceptance tests required | Full IEC-compliant testing performed for each unit |

Applications and Importance

- Power generation plants

- Steel and metal processing facilities

- Chemical and petrochemical industries

- Mining and mineral processing

- Large-scale water and wastewater treatment plants

Summary

By adhering to IEC standards, the YKS Series High-Voltage Three-Phase Induction Motor guarantees safety, efficiency, and reliability. Compliance ensures that the motor meets rigorous global quality requirements, providing industrial operators with confidence in performance, durability, and long-term operational stability.

Conclusion: Why Choose the YKS Series High-Voltage Three-Phase Induction Motor?

The YKS Series High-Voltage Three-Phase Induction Motor stands out as a highly reliable, efficient, and durable solution for demanding industrial applications. Its combination of high-voltage capability, robust squirrel cage rotor design, advanced water-cooling system, and compliance with IEC standards makes it ideal for continuous heavy-duty operation.

Key advantages include:

- High Efficiency: Lower energy consumption and improved operational costs compared to standard motors.

- Robust Design: Reinforced rotor, high-quality insulation, and durable construction ensure long service life.

- Advanced Cooling: Water-cooled systems provide stable temperatures, reduce noise, and allow higher power density.

- Reliability: Minimal maintenance requirements and high resistance to harsh industrial environments.

- Global Standards Compliance: IEC certification guarantees safety, performance, and international compatibility.

For industries requiring large-scale, continuous, and reliable motor operation—such as steel production, mining, chemical plants, and water treatment facilities—the YKS Series High-Voltage Three-Phase Induction Motor offers an optimal balance of performance, efficiency, and durability. Its design ensures operators can achieve consistent productivity while minimizing downtime and maintenance costs.

In conclusion, the YKS Series is not just an electric motor—it is a dependable industrial partner designed to meet the rigorous demands of modern heavy-duty applications.

FAQ

1. What industries are best suited for the YKS Series High-Voltage Three-Phase Induction Motor?

The YKS Series is ideal for heavy-duty industrial applications that require continuous high-power operation. Typical industries include steel and metal processing, mining, chemical and petrochemical plants, large-scale water treatment facilities, and power generation plants.

2. How does water cooling improve the performance of the YKS Series motor?

Water cooling efficiently removes heat from the motor, maintaining stable operating temperatures even under heavy loads. This increases efficiency, reduces noise and vibration, allows higher power density, and extends the motor’s service life compared to standard air-cooled systems.

3. Why is IEC compliance important for the YKS Series motor?

IEC compliance ensures the motor meets internationally recognized safety, efficiency, and performance standards. It guarantees reliable operation, reduced risk of failure, and compatibility with industrial systems worldwide, making the YKS Series a dependable choice for critical applications.

English

English русский

русский Français

Français عربى

عربى