What’s the “Black Tech” Behind TAW Three-Phase Synchronous Induction Motors?

Unveiling the Core Principle and Advantages

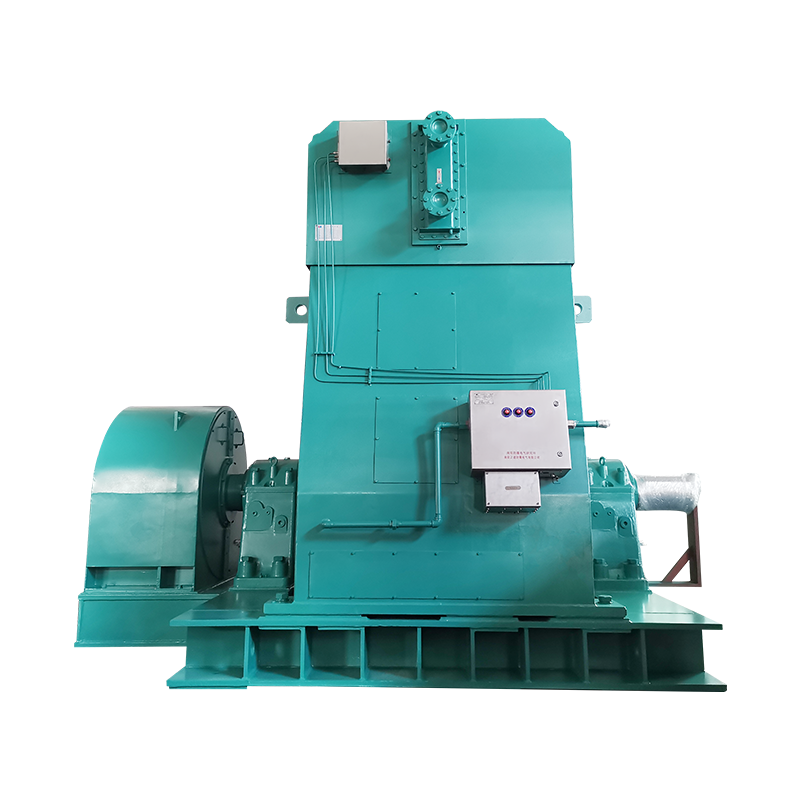

In the heart of modern industry, where a vast array of large-scale machinery operates, the electric motor plays an indispensable role. Among the numerous options available, the TAW three-phase synchronous induction motor distinguishes itself with its unique design and exceptional performance. It brilliantly combines the constant-speed characteristics of synchronous motors with the straightforward structure of induction motors, creating an efficient and stable driving solution. When the motor is energized, it not only generates torque through induced currents in the rotor windings, much like an induction motor, but it also employs an external excitation device to lock the rotor magnetic field to the synchronous speed during operation. This hybrid design, which leverages the strengths of both motor types, ensures that the equipment maintains a stable speed even under fluctuating loads. Moreover, its superior efficiency and power factor make it an ideal power source for a wide range of heavy-duty industrial applications.

Tailored to Your Needs: The Flexibility of Voltage, Frequency, and Rotation

A significant advantage of the TAW series motor lies in its high degree of customization. Recognizing that different countries and regions have varying power grid standards and that industrial users have diverse requirements, this motor can be supplied with different voltages and frequencies to meet specific needs. Whether it’s the 50Hz grid commonly found in Europe or the 60Hz grid prevalent in North America, a suitable solution can be provided. Furthermore, the motor’s direction of rotation is also optional and can be configured as per the customer’s request. This flexibility is crucial for applications such as pumping stations or fans, where the direction of rotation is a critical factor. The adaptable design of the TAW motor allows it to be seamlessly integrated with a wide variety of complex machinery across global markets, offering tremendous convenience to users.

The Art of Starting: Navigating Direct and Reduced-Voltage Strategies

The starting process is a critical phase in a motor’s operation, especially for high-power units. The TAW series motor is designed to allow for direct full-voltage starting, a method that is both simple and highly effective, enabling the motor to reach its operating state quickly. This approach, however, is contingent on the user’s power grid having a sufficiently robust capacity to handle the massive current surge during startup. When the power grid capacity is limited or there are strict requirements regarding voltage fluctuations, reduced-voltage starting becomes a more prudent choice. This method limits the starting current by lowering the voltage at the motor terminals. It’s important to note that while the dynamic current of the motor is proportional to the terminal voltage, the starting torque is proportional to the square of the terminal voltage. Consequently, while reduced-voltage starting effectively controls the starting current, it also significantly reduces the starting torque. Therefore, users must carefully weigh the trade-offs between starting current and starting torque based on their specific load conditions to ensure a smooth and reliable startup.

The Inner Heart: The Secrets of the Silicon-Controlled Excitation Device

The ability of the TAW motor to achieve synchronous operation is largely due to its sophisticated excitation device. This series of motors typically utilizes a silicon-controlled excitation device, which employs thyristor technology to precisely regulate the current flowing through the excitation winding, thereby controlling the magnetic field strength of the rotor. Compared to traditional mechanical or DC excitation methods, this system offers several advantages, including fast response times, high control accuracy, compact size, and simplified maintenance. It can adjust the excitation current in real-time based on the motor’s operating conditions (such as load changes), ensuring the motor runs optimally and maintains a stable synchronous speed. This not only enhances the motor’s operational efficiency but also positively impacts the power factor of the entire electrical system. The silicon-controlled excitation device is, without a doubt, the “inner heart” that enables the TAW motor to achieve its high-efficiency and stable performance.

Installation and Maintenance: The Unsung Details

In the practical application of TAW series motors, certain seemingly minor details are of paramount importance. A crucial limitation to be aware of is that the motor shaft extension cannot withstand external radial or axial forces. This is because the shaft system of the TAW motor is primarily designed to transmit torque, not to endure additional bending moments or thrusts. Any unnecessary external force could lead to bearing damage, shaft bending, or even complete motor failure. Therefore, during installation, it is essential to ensure that the mechanical equipment connected to the motor, such as couplings or pulleys, is perfectly aligned and that all unnecessary external stress is eliminated. Additionally, routine maintenance is equally vital. This includes regularly checking the status of the excitation device, cleaning dust from the motor exterior to ensure proper heat dissipation, and other simple yet critical tasks. These practices are key to guaranteeing the long-term stable and reliable operation of the motor, maximizing its performance and extending its service life.

English

English русский

русский Français

Français عربى

عربى