Why Do High-Voltage Motors Demand a Superior Insulation System?

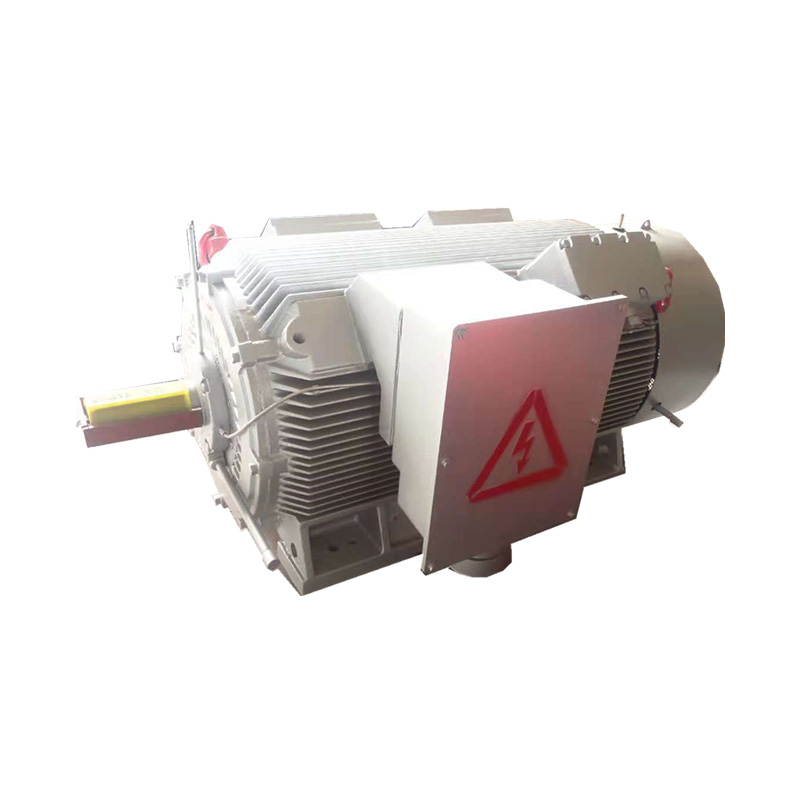

The Y2 series high-voltage three-phase induction motor, with its impressive stature ranging from H:355-630mm, stands as a cornerstone of modern industrial power. These robust machines are the driving force behind critical infrastructure such as water pumps, ventilation fans, and compressors. Operating in demanding environments, they must withstand a barrage of challenges, including voltage fluctuations, temperature extremes, humidity, and corrosive agents. The motor’s internal windings, its very heart, are constantly subjected to the immense stress of high-voltage currents. An inadequately designed or poorly manufactured insulation system can lead to catastrophic failure, resulting in production downtime and significant financial loss. This is precisely why a superior insulation system is paramount for ensuring a high-voltage motor’s stability and longevity. The Y2 series motors were engineered with these harsh conditions in mind, featuring a unique insulation system designed to intrinsically enhance reliability. This forward-thinking approach is not just a technological innovation; it is a profound commitment to the continuity and safety of industrial operations.

VPI Insulation Process: The Unseen Guardian of Motor Performance

At the core of the Y2 series motor’s insulation prowess is the Vacuum Pressure Impregnation (VPI) technology, which acts as an invisible guardian, providing the windings with an impenetrable layer of protection. This sophisticated process begins by placing the motor’s stator in a vacuum chamber to completely remove air and moisture from within the winding gaps and insulation materials. The stator is then submerged in an insulating varnish, and pressure is applied to ensure the varnish permeates every minuscule crevice. Once cured, this process creates a solid, void-free, and highly durable insulation layer. This advanced technique dramatically boosts the main and inter-turn insulation’s ability to resist electrical impulses, allowing the motor to effectively withstand instantaneous voltage spikes and preventing insulation breakdown during startup or grid fluctuations. Furthermore, the VPI process endows the insulation system with exceptional thermal resistance, meeting the stringent Class F insulation standard and ensuring the motor maintains stable performance even in high-temperature environments.

The Secret of a Powerful Core: Cast Aluminum Rotor and High-Rigidity Frame

The reliable operation of a motor hinges not only on its insulation but also on its mechanical integrity. Y2 series high-voltage motors are equipped with cast aluminum rotors, a design choice that significantly enhances their mechanical strength and reliability. Unlike traditional welded rotors, this single-piece casting eliminates potential weak points from welds, making the rotor far more robust. The cast aluminum material is also lightweight with excellent thermal properties, which helps to reduce operational temperature rise and ensures stability during prolonged, high-load operation. In addition, the motor frame itself is a marvel of engineering. The exterior is adorned with dense cooling fins, which not only increase the surface area for heat dissipation but, more importantly, lend the frame exceptional mechanical strength and rigidity. This robust frame effectively resists operational vibrations and external impacts, providing a solid foundation and protection for the motor’s internal precision components, thereby guaranteeing long-term, reliable operation.

Efficiency and Serenity: The Innovative Cooling System Design

Effective heat dissipation is a critical determinant of a motor’s performance and lifespan. The Y2 series high-voltage motors feature a totally-enclosed design with an IP54/IP55 degree of protection. This means the internal windings and rotor are effectively sealed off from the external environment, preventing the ingress of dust and water. This is particularly advantageous for industrial settings characterized by high levels of dust, humidity, or corrosive gases. The key to its superior heat management lies in the innovative external fan design. This is not a simple fan, but a highly engineered, one-way fan that boasts low noise, high efficiency, and strong air pressure. This design ensures a powerful and consistent airflow that effectively dissipates heat from the motor frame’s surface. By being a single-direction fan, it avoids the turbulence and inefficiency that can occur with reversible fans. This creative solution not only ensures optimal cooling but also significantly reduces operational noise, contributing to a more comfortable and quieter working environment.

How to Select the Right Y2 Series High-Voltage Motor for Your Industrial Application?

Choosing the ideal Y2 series high-voltage motor for a specific industrial application requires a meticulous and comprehensive evaluation. You must first clearly define the motor’s operating environment—considering factors such as temperature, humidity, and the presence of corrosive gases or heavy dust. These conditions will directly dictate the necessary degree of protection. Next, it’s crucial to understand the load characteristics of the driven equipment, including starting torque, inertia, and duty cycle, to ensure the selected motor provides consistent and reliable power throughout its operation. For applications requiring frequent starts and stops, special attention should be paid to the motor’s electrical impulse resistance and rotor strength. Furthermore, a thorough assessment of the motor’s efficiency is essential. While a high-efficiency motor might have a slightly higher initial cost, it can lead to substantial energy savings and reduced operational expenses over the long term. Finally, don’t overlook maintenance costs and after-sales support. Choosing a well-designed, highly reliable, and easy-to-maintain motor can significantly minimize losses from unexpected downtime, ultimately delivering sustainable economic benefits.

English

English русский

русский Français

Français عربى

عربى