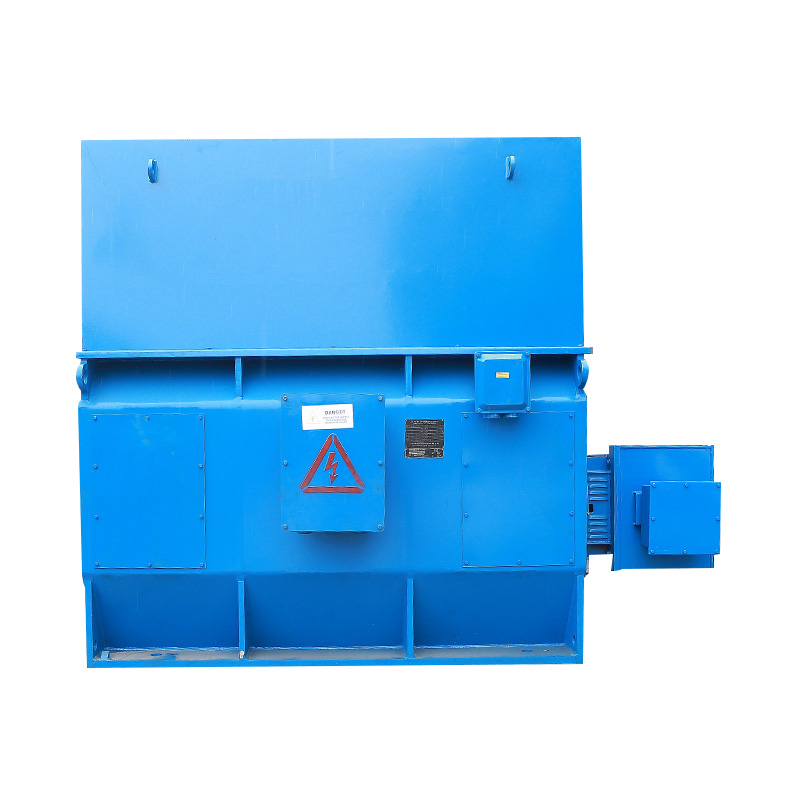

YR Series High-Voltage Slip Ring Motors: Why Are They the Preferred Choice for Heavy-Duty Applications?

Addressing the Challenges of Heavy Loads with Slip Ring Technology

In the landscape of modern industrial production, numerous pieces of equipment, such as large-scale ball mills, crushers, and compressors, demand an immense amount of torque to initiate their operation. The sheer inertia of these heavy loads poses a significant challenge to conventional motors. When confronted with such demanding starting conditions, standard squirrel-cage motors often draw excessive starting currents, causing disturbances to the power grid and potentially failing to generate sufficient starting torque. The YR series of high-voltage slip ring motors was engineered precisely to overcome these hurdles. By incorporating starting resistors into the rotor circuit, these motors effectively limit the inrush current while simultaneously boosting the starting torque. This ingenious design enables heavy machinery to transition smoothly and reliably from a static state to full operation, thereby safeguarding the stability of the power grid and the integrity of the equipment itself. The unique and robust design of the YR series makes it an ideal choice for a wide array of complex and demanding industrial scenarios, cementing its position as a leading solution for heavy-duty drive applications.

The Heart of the Machine: A Deep Dive into Core Technologies

The exceptional performance of the YR series high-voltage slip ring motors in heavy-duty applications is a testament to their sophisticated internal engineering and structural design. These motors are constructed with Class F insulation, a superior material capable of withstanding higher operating temperatures. This ensures the reliability of the insulation under prolonged, high-load conditions, which in turn significantly extends the motor’s operational lifespan. Furthermore, the motor’s box-type construction not only lends it a sleek aesthetic but, more importantly, provides outstanding mechanical strength and thermal dissipation capabilities. This structural design markedly enhances the motor’s resilience to external shocks and vibrations, guaranteeing smooth and stable operation. Optimized electromagnetic design combined with precision manufacturing processes allows the YR series to exhibit superior characteristics like high efficiency and low vibration. This translates directly into reduced energy consumption and provides a smoother power output to the machinery, which in turn minimizes wear on mechanical components and lowers overall maintenance costs.

A Comprehensive Selection Guide: Finding the Right Motor for Your Needs

Selecting the appropriate motor is foundational to ensuring the efficient and safe operation of any industrial equipment. For the YR series high-voltage slip ring motors, the selection process requires a holistic consideration of several critical parameters. Foremost, it is crucial to match the motor’s rated voltage and frequency (e.g., 3kV-13.8kV, 50Hz) with the power grid’s supply standards to prevent performance degradation or damage caused by voltage instability or frequency deviations. Second, the motor’s rated power should be chosen judiciously based on the equipment’s actual power requirements, with a suitable margin to accommodate potential overloads. Moreover, the protection degree is a factor that cannot be overlooked. The IP23 protection rating of the YR series indicates its ability to prevent the ingress of solid objects larger than 12.5 mm in diameter and to resist water spray from any direction. For environments that are dusty or humid, opting for a motor with a higher protection degree is a prudent choice. Lastly, the cooling method is vital. The self-fan cooling system used by the YR series, which dissipates heat through the rotation of its own fan, is suitable for most working conditions, although alternative cooling solutions might be necessary in especially hot or enclosed spaces.

Ensuring Longevity: Key Maintenance and Upkeep Practices

The long-term reliability of any motor is contingent upon meticulous routine maintenance and care. For the YR series high-voltage slip ring motors, the core of maintenance revolves around lubrication and monitoring. The bearings on the motor’s rotor bear immense mechanical loads, making regular bearing lubrication essential. It is imperative to adhere to the manufacturer’s recommended schedule and grease specifications to ensure the smooth operation of the bearings and prevent damage from friction. Simultaneously, consistently monitoring the motor’s operating temperature is an effective way to preemptively identify potential issues. Abnormal temperature increases often serve as a precursor to internal problems, such as winding insulation aging, inadequate ventilation, or aggravated bearing wear. In addition to lubrication and temperature checks, periodic inspections of the tightness of all components, the wear of the carbon brushes, and the cleanliness of the slip ring surface are indispensable. Addressing any anomalies promptly is critical to preventing minor issues from escalating into major failures, thereby guaranteeing uninterrupted production and the safety of the equipment.

More Than Just a Driver: The Value of the Motor in Industry

The role of the YR series high-voltage slip ring motor in industrial production extends far beyond simply providing motive force. It represents a comprehensive optimization of both production efficiency and energy costs. Its high-efficiency characteristics mean it consumes less electricity for the same power output. In an era of escalating electricity costs, this directly translates into significant cost savings. Concurrently, its exceptional reliability and stability substantially reduce downtime caused by equipment failures, ensuring continuous production line operation and boosting overall productivity. Furthermore, by providing smooth starting and running, it mitigates mechanical stress on the machinery, extending the lifespan of the entire system, including the transmission components, and indirectly lowering repair and replacement expenses. Consequently, investing in a high-quality YR series slip ring motor is not merely a decision about a power source for a piece of equipment; it is a strategic investment in the long-term growth and sustainable operation of an enterprise.

English

English русский

русский Français

Français عربى

عربى