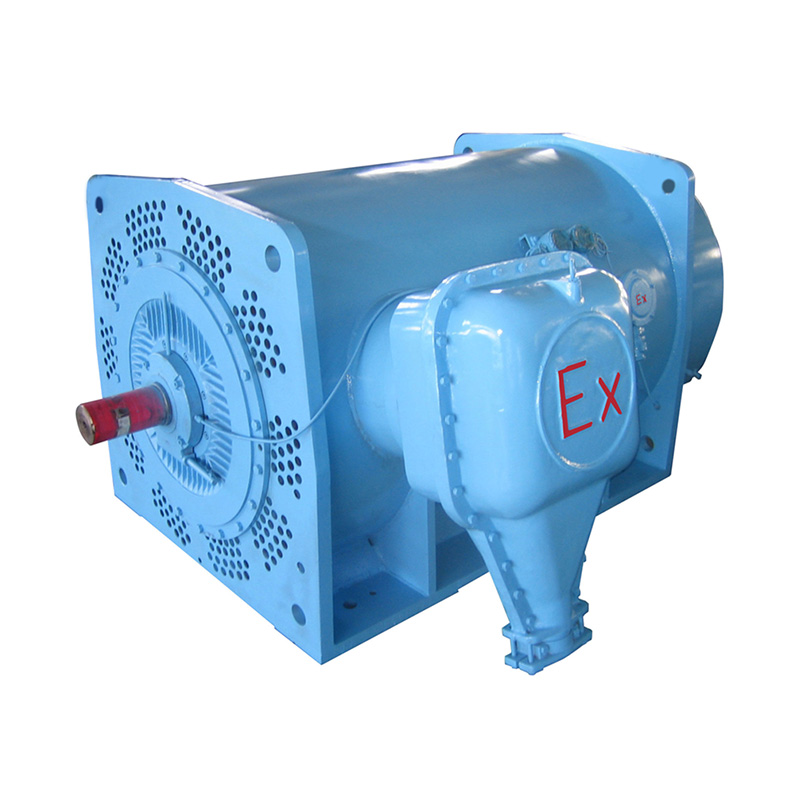

T SERIES THREE-PHASE SYNCHRONOUS INDUCTION MOTOR Technical Analysis and Application Advantages

Introduction

The T SERIES THREE-PHASE SYNCHRONOUS INDUCTION MOTOR plays an essential role in modern industrial systems, providing reliable performance and adaptability across a wide range of applications. With its ability to operate under different voltages and frequencies, this motor is designed to meet diverse operational requirements. In addition, the flexibility of choosing the rotation direction according to specific needs makes it suitable for customized solutions.

By combining efficiency, stability, and versatile control features, the T SERIES THREE-PHASE SYNCHRONOUS INDUCTION MOTOR has become a preferred choice in industries that demand high performance and consistent operation.

Core Structure and Operating Principle

Stator

The stator generates a rotating magnetic field when powered by a three-phase supply. It provides the foundation for efficient energy conversion.

Rotor

The rotor interacts with the stator’s magnetic field to create torque. Depending on the load conditions, the rotor maintains synchronous operation, ensuring consistent speed.

Excitation Device

The excitation system of the motor is typically controlled by a silicon-controlled rectifier (SCR). This method provides reliable control over excitation current, ensuring stable synchronization during operation.

Key Characteristics

| Feature | Description |

| Excitation Method | Silicon-controlled rectifier (SCR) for precise control |

| Starting Mode | Direct full-voltage start or reduced-voltage start (as required) |

| Dynamic Current Relationship | Proportional to the applied terminal voltage |

| Starting Torque Relationship | Proportional to the square of the applied terminal voltage |

| Shaft Extension Load Tolerance | Not designed to withstand external radial or axial forces |

Starting Methods and Performance

Direct Full-Voltage Starting

The motor allows direct starting at full terminal voltage. This method provides high starting torque and is suitable when the power grid capacity permits.

Reduced-Voltage Starting

If the power grid cannot support direct full-voltage starting, reduced-voltage starting is recommended. This method lowers the inrush current, protecting both the motor and the electrical system.

Relationship Between Current, Voltage, and Torque

One of the key performance characteristics of the T SERIES THREE-PHASE SYNCHRONOUS INDUCTION MOTOR is the proportional relationship between current, torque, and terminal voltage during startup.

| Terminal Voltage (% of Rated) | Starting Current (% of Rated) | Starting Torque (% of Rated) |

| 100% | 100% | 100% |

| 80% | 80% | 64% |

| 60% | 60% | 36% |

| 40% | 40% | 16% |

- Dynamic current is directly proportional to the terminal voltage.

- Starting torque is proportional to the square of the terminal voltage.

Customization and Flexible Control

Voltage and Frequency Customization

The motor can be manufactured to operate under different voltage and frequency standards. This ensures compatibility with regional power grid specifications and industrial demands.

| Parameter | Standard Option | Customizable Range* |

| Voltage | 380 V | 220 V – 13.8 kV |

| Frequency | 50 Hz | 50 Hz / 60 Hz |

| Phase Configuration | Three-phase | Optional within design |

*Values are illustrative and depend on user requirements.

Reversible Rotation Direction

The rotation direction of the T SERIES THREE-PHASE SYNCHRONOUS INDUCTION MOTOR can be adjusted according to customer needs. This feature enables the motor to integrate easily into systems that require forward and reverse operation.

Adaptability to Power Conditions

By supporting both direct full-voltage and reduced-voltage starting, the motor offers enhanced adaptability. This ensures that users with limited grid capacity can still benefit from reliable motor operation.

Application Scenarios and Advantages

Application Scenarios

- Metallurgy and Mining: Ensures consistent operation under heavy load conditions.

- Power Generation Plants: Provides stable synchronous speed, ideal for auxiliary equipment.

- Petrochemical Industry: Handles demanding environments where reliability and customization are crucial.

- Manufacturing Lines: Supports variable processes requiring precise speed control.

- Pumping and Ventilation Systems: Offers dependable performance for large-scale fluid or air movement.

Advantages Summary

| Advantage | Description |

| Stable Synchronous Speed | Maintains constant speed under varying load conditions. |

| Flexible Starting Methods | Supports both full-voltage and reduced-voltage starting. |

| Custom Voltage & Frequency Options | Compatible with different power grid standards worldwide. |

| Reversible Rotation | Rotation direction can be selected based on operational requirements. |

| Reliable Excitation Control | SCR-based excitation ensures precise and stable operation. |

Conclusion

The T SERIES THREE-PHASE SYNCHRONOUS INDUCTION MOTOR combines reliability, efficiency, and flexibility, making it an ideal choice for a wide range of industrial applications. Its robust design, including a stator, rotor, and SCR-controlled excitation system, ensures stable operation under various load conditions.

With multiple starting methods, customizable voltage and frequency options, and reversible rotation capabilities, this motor meets diverse operational requirements while maintaining safe and efficient performance. Furthermore, its proportional relationship between starting current, torque, and terminal voltage allows precise control during startup, protecting both the motor and the power system.

In summary, the T SERIES THREE-PHASE SYNCHRONOUS INDUCTION MOTOR provides:

- High reliability and stable synchronous speed

- Adaptability to different industrial and regional power conditions

- Flexible control for forward and reverse operations

- Efficient and safe starting options

As industries continue to demand higher efficiency, precision, and customization, the T SERIES THREE-PHASE SYNCHRONOUS INDUCTION MOTOR remains a versatile and dependable solution for modern industrial systems.

Frequently Asked Questions (FAQ)

1. What applications are suitable for the T SERIES THREE-PHASE SYNCHRONOUS INDUCTION MOTOR?

The T SERIES THREE-PHASE SYNCHRONOUS INDUCTION MOTOR is suitable for industries requiring stable performance and flexible operation, including metallurgy, mining, power generation, petrochemical production, manufacturing lines, and large-scale pumping or ventilation systems. Shanghai Pinxing Explosion-proof Motor Co., Ltd. ensures that all motors are designed to meet rigorous industrial standards for reliability and efficiency.

2. Can the motor be customized for different voltages, frequencies, or rotation directions?

Yes, the T SERIES THREE-PHASE SYNCHRONOUS INDUCTION MOTOR can be customized to operate under different voltage and frequency standards, and its rotation direction can be selected according to operational requirements. Shanghai Pinxing Explosion-proof Motor Co., Ltd. specializes in providing tailored motor solutions to meet the unique needs of each customer.

3. What are the advantages of the starting methods for this motor?

The motor supports both direct full-voltage starting and reduced-voltage starting. Direct starting provides high starting torque for systems with sufficient grid capacity, while reduced-voltage starting limits inrush current to protect the motor and electrical system. Shanghai Pinxing Explosion-proof Motor Co., Ltd. integrates these features into every design, ensuring safe, efficient, and reliable motor startup.

English

English русский

русский Français

Français عربى

عربى