What are the Key Advantages of Using THREE PHASE WOUND ROTOR MOTORS in Industrial Applications?

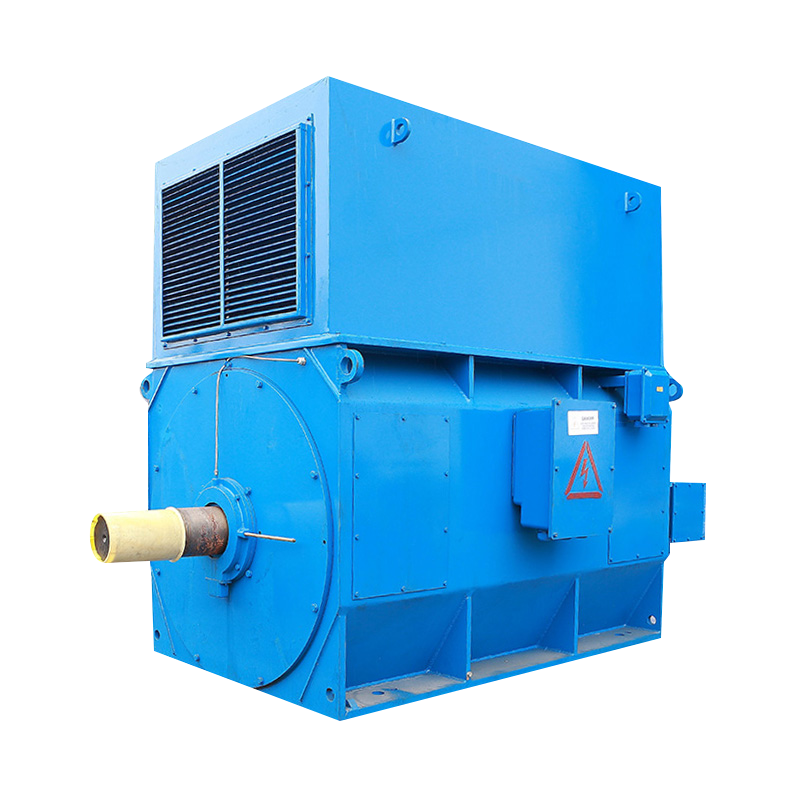

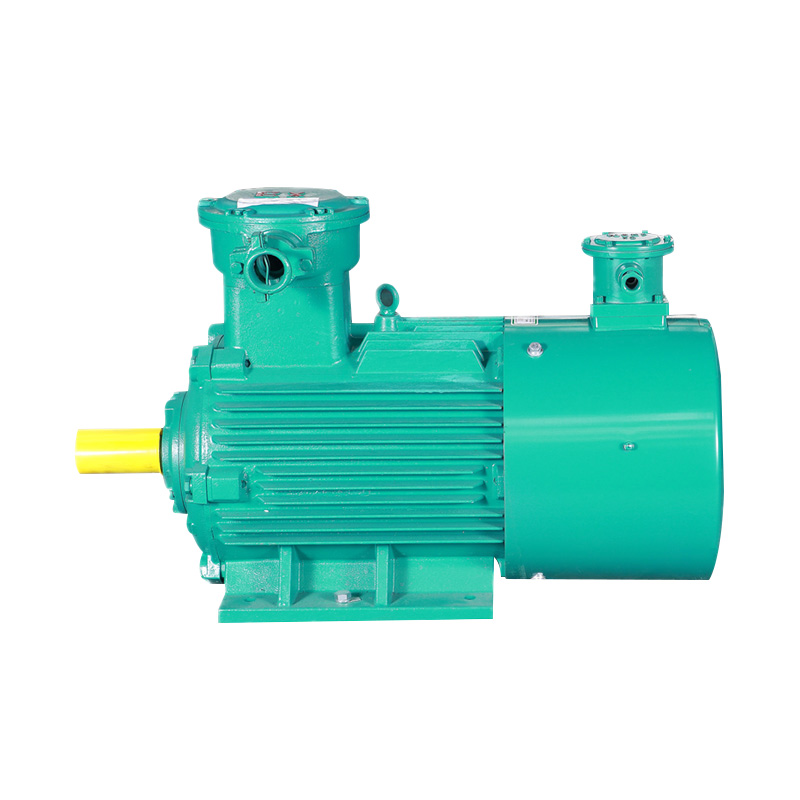

In an era dominated by variable frequency drives (VFDs), one might consider the three-phase wound rotor motor a legacy technology. Yet, walk into any heavy-duty processing plant, mine, or large-scale material handling facility, and you'll find these workhorses reliably powering through the most demanding tasks. The question isn't about obsolescence, but specialization: for specific high-torque, high-inertia applications, the wound rotor motor offers a combination of performance, robustness, and cost-effectiveness that modern alternatives often struggle to match. This article delves beyond the basics, providing an engineer-level analysis of the key advantages that make three-phase wound rotor motors indispensable in industrial applications, from controlled starting to practical maintenance.

Foundational Principle: The Power of External Rotor Control

Unlike a squirrel-cage motor whose rotor circuit is permanently shorted, the defining feature of a wound rotor motor is its three-phase rotor winding, brought out to the stator via slip rings and brushes. This architecture allows for the connection of external resistors or electronic controls into the rotor circuit. This simple yet profound difference enables direct manipulation of the motor's torque-speed characteristic. By increasing the external rotor resistance at startup, the rotor's effective impedance rises, which simultaneously limits inrush current and maximizes available torque right from zero speed—a capability that is intrinsic to the motor's design.

Core Advantage 1: Superior Starting Performance for Heavy Loads

This is where wound rotor motors truly excel. Their ability to provide high starting torque with low starting current solves two critical industrial problems: mechanical stress on driven equipment and electrical stress on the power supply.

Conquering High Inertia: The Ideal Choice for Crushers & Mills

When comparing a three-phase wound rotor motor vs squirrel cage for crusher application, the wound rotor's superiority is clear. Crushers, ball mills, and large fans present massive rotational inertia. A standard squirrel-cage motor starting across-the-line would draw 600-800% of full-load current while providing only 150-200% of rated torque, causing severe grid dips and prolonged, stressful acceleration. A wound rotor motor with properly sized external resistors can deliver 200-250% of full-load torque while drawing only 150-200% of current. This results in a smooth, controlled, and faster acceleration of the high-inertia load, minimizing wear on gears, couplings, and the driven machinery itself.

Precision in Motion: The Safety-Critical Solution for Hoists

The question of why use a wound rotor motor for hoist applications centers on control and safety. Hoists and cranes require not just high starting torque to lift a load, but, more importantly, precise control during acceleration and deceleration to prevent load swing. The stepped resistance control of a wound rotor motor allows operators to smoothly progress through acceleration and, crucially, use resistors for controlled electrical braking during lowering. This provides an inherent "soft-start" and "soft-stop" capability that enhances safety, reduces mechanical shock, and allows for precise load spotting, which is difficult to achieve as reliably with a basic squirrel-cage motor setup.

Core Advantage 2: Robust and Economical Speed Control

For applications requiring limited speed variation, wound rotor motors offer a remarkably sturdy solution. Understanding how to control speed of a three phase wound rotor motor is straightforward: by varying the resistance in the rotor circuit, you change the motor's slip, and thus its speed. More resistance equals higher slip and lower operating speed. This method provides a simple, cost-effective, and robust means of speed control, especially in harsh environments where delicate electronics might fail.

- Traditional Stepped Resistors: Bulky but extremely robust banks of resistors switched via contactors. Ideal for dirty, hot environments.

- Liquid Rheostats: Provide smoother acceleration by varying the electrolyte level or plate immersion, often used in very high-power slip-ring motors.

- Solid-State Rotor Controllers: Modern electronic choppers that vary effective resistance by PWM control, offering better efficiency and finer control than stepped resistors.

When evaluating speed control options, a key consideration for engineers is the total cost of ownership and environmental suitability. The table below contrasts the wound rotor solution with the ubiquitous VFD-driven squirrel-cage motor for a typical high-power, limited speed range application.

| Feature | Wound Rotor Motor with Resistance Control | Squirrel-Cage Motor with VFD |

| Initial Cost (High Power) | Generally lower for the motor and control system. | Significantly higher, especially for drives rated for high starting torque. |

| Speed Control Range | Limited (typically 50-100% of synchronous speed). Best for fixed or stepped speed reduction. | Very wide (0-120%+). Excellent for precise, continuous speed variation. |

| Environmental Ruggedness | Excellent. Resistor banks and motor are highly tolerant of dust, moisture, and temperature swings. | Moderate to Poor. VFDs require clean, cool environments or expensive protective enclosures. |

| Harmonics & Power Factor | Does not generate line-side harmonics. Power factor decreases with speed reduction. | Generates harmonics requiring mitigation. Can maintain high power factor across the range. |

| Maintenance Complexity | Mechanical/electrical (brushes, resistors, contactors). Predictable and often simple. | Electronic. Requires specialized knowledge for troubleshooting. |

Core Advantage 3: Inherent Grid and Equipment Protection

The most direct electrical benefit is answering how do wound rotor motors reduce inrush current. By design, the starting current is typically held to 150-200% of FLC, compared to 600-800% for a DOL squirrel-cage motor. This has significant commercial implications:

- Reduced Grid Impact: Prevents voltage sags that can disrupt other sensitive equipment on the same supply.

- Lower Infrastructure Cost: Allows for the use of smaller transformers and cabling, reducing initial capital expenditure.

- Inherent Soft Starting: The controlled torque rise protects the driven equipment from sudden mechanical shocks, extending the lifespan of gearboxes, conveyors, and couplings.

Industry Context: The Evolving Niche in a VFD World

While VFD adoption continues to grow, the wound rotor motor has not remained static. Its niche is being reinforced by both persistent demand and technological updates. According to a 2024 electro-technical market analysis focused on heavy industry, the demand for high-torque starting solutions in emerging markets with less stable grid infrastructure has seen a steady 3-5% annual growth, with modernized wound rotor systems featuring solid-state rotor controllers capturing a significant share. Furthermore, the latest 2023 revision of the IEC 60034-30-1 standard for motor efficiency classes, while primarily targeting squirrel-cage motors, has spurred development in optimizing the complete drive system efficiency of wound rotor applications, including improved control schemes for external resistors to minimize slip losses during steady-state operation.

Source: IEC - International Electrotechnical Standards & Industry Market Analysis Reports

Ensuring Long-Term Reliability: Maintenance Best Practices

The performance advantages of wound rotor motors are contingent on proper upkeep. A structured maintenance program is essential.

Proactive Care: The Slip Ring Maintenance Guide for Wound Rotor Induction Motor

The slip ring and brush assembly is the system's primary wear component. Best practices include:

- Regular Inspection & Cleaning: Check for dust buildup (conductive carbon dust is particularly harmful) and clean with a non-filament cloth and appropriate cleaner.

- Brush Wear & Pressure: Measure brush length regularly and replace per manufacturer's spec. Ensure spring pressure is even and correct to maintain good contact and minimize sparking.

- Slip Ring Surface Condition: Monitor for grooving, pitting, or uneven wear. Light maintenance with fine abrasive paper may suffice; severe cases require professional re-machining.

- Spark Observation: Some sparking is normal at the trailing edge of the brush. Excessive sparking (beyond IEC/GB standards) indicates issues with pressure, ring surface, or brush grade.

A Practical Troubleshooting Three Phase Wound Rotor Motor Common Problems

Quick-reference guide for common issues:

- Excessive Brush Sparking/Wear: Check brush pressure, grade, and slip ring surface condition. Ensure rings are clean and concentric.

- Motor Runs Slow/Overheats: Likely a fault in the external resistance circuit (open connection, failed contactor, stuck step). Check resistance bank and control sequence.

- Uneven Phase Current: Could indicate an open circuit in one rotor phase (broken lead, severely worn brush), or an imbalance in the external resistors.

- Vibration/Noise: Check for worn bearings (common to all motors) but also inspect for uneven brush drag or mechanical issues with the slip ring assembly.

FAQs: Three-Phase Wound Rotor Motors

1. Are wound rotor motors less efficient than VFD-driven motors?

At full speed with the rotor shorted, their efficiency is comparable to a similar class squirrel-cage motor. During speed reduction via resistance, efficiency drops as slip losses are dissipated in the resistors. A modern VFD can be more efficient across a wide speed range. However, for fixed-speed or limited-range applications, the total system efficiency difference may be negligible, and the lower initial cost and higher ruggedness of the wound rotor system can offer a better total cost of ownership.

2. Is brush maintenance a major drawback?

It is a consideration, not necessarily a drawback. Brush and slip ring maintenance is a predictable, scheduled task. In harsh environments, this mechanical maintenance is often preferred over the failure of sensitive VFD electronics. Modern brush materials and designs have significantly extended service intervals, sometimes exceeding 12-18 months of continuous operation.

3. Can a wound rotor motor be used with a VFD?

Yes, in a configuration called a "doubly-fed" system, but it is complex and uncommon. More practically, VFDs can be used on the stator side of a wound rotor motor (with the rotor shorted), but this negates its starting advantages and is rarely cost-effective compared to using a standard squirrel-cage motor.

4. What are the main reasons to choose one today?

The primary decision drivers are: 1) Requirement for very high starting torque with limited inrush current (for crushers, compressors), 2) Need for simple, rugged speed control in a harsh environment (dirty, wet, hot), and 3) Applications where controlled acceleration/deceleration is critical for safety or process reasons (hoists, large conveyors).

5. How do I know if my application needs one?

Perform a detailed drive train analysis. Key questions: What is the WR2 (moment of inertia) of the load? What is the required breakaway and acceleration torque? What are the grid limitations? What is the operating environment? If the analysis points to high inertia, high starting torque, and a need for controlled starting within grid constraints, a wound rotor motor should be a top contender.

English

English русский

русский Français

Français عربى

عربى